- Industrial machines and equipment

- Printing, Marking and Engraving

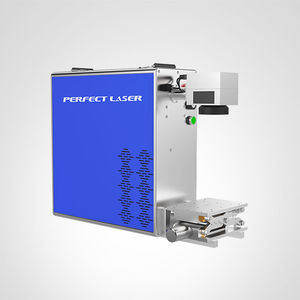

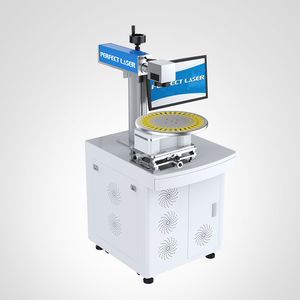

- Fiber laser marking machine

- Perfect Laser Co., Ltd. (China)

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Fiber laser marking machine PEDB-610plasticpaperfor paper

Add to favorites

Compare this product

Characteristics

- Technique

- fiber laser

- Material

- plastic, paper, for paper

- Applications

- industrial, for electronic components, for PCB, cable

- Other characteristics

- automated, air-cooled, programmable, computer-controlled, traceability, with touch screen

- Power

20 W, 30 W, 50 W, 100 W

(0.03 hp, 0.04 hp, 0.07 hp, 0.14 hp)- X travel

110 mm

(4.33 in)- Y travel

110 mm

(4.33 in)- Speed

Max.: 300 m/min

Min.: 0 m/min

Description

The flying laser marking machine uses a high-quality laser beam with a large depth of field to ensure fast marking. At the same time,it works with an intelligent red light positioning system to make the mark more high-quality, rich in mark content, and diverse in mark materials.

The intelligent touch-screen control system, combined with the highly intelligent core chip, enables the flying laser marking machine to operate stress-free, meeting large-scale industrial online production and having the ability to work continuously 24 hours.

1. High-quality laser beam: The flying laser marking machine uses imported lasers, the laser source has high performance and an average trouble-free use time of 100,000+ hours. A variety of laser powers are available, which can provide the high-quality marking you require within a reasonable and effective range.

2. Simple and easy to operate: The flying laser marking machine has an intelligent touch-screen control system, combined with a high-intelligent core chip, ensures stable and stress-free operation.

3. High-speed galvanometer: The marking speed is as high as 18000 mm/s, which can print more complex contents and patterns at the same time.

4. Easy to integrate: The quartz high-transparency field lens provides a large field of view and a wide focusing and marking range.

5. The 720-degree all-round rotatable marking head can easily cope with various production line conditions.

6. Safety: Equipped with the Perfect Laser traceability system, the cable laser marking machine is easy to track the whereabouts of products and improve product safety.

Catalogs

No catalogs are available for this product.

See all of Perfect Laser Co., Ltd. (China)‘s catalogsOther Perfect Laser Co., Ltd. (China) products

Laser Marking Machine

Related Searches

- Perfect Laser Co. Ltd. marking machine

- Perfect Laser Co. Ltd. laser marking machine

- Perfect Laser Co. Ltd. metal marking machine

- Perfect Laser Co. Ltd. benchtop marking machine

- Perfect Laser Co. Ltd. printing machine

- Perfect Laser Co. Ltd. industrial printer

- Perfect Laser Co. Ltd. plastic marking machine

- Perfect Laser Co. Ltd. industrial marking machine

- Perfect Laser Co. Ltd. automatic marking machine

- Perfect Laser Co. Ltd. compact marking machine

- Perfect Laser Co. Ltd. high-speed marking machine

- Perfect Laser Co. Ltd. fiber laser marking machine

- Perfect Laser Co. Ltd. color printing machine

- Perfect Laser Co. Ltd. laser engraving machine

- Perfect Laser Co. Ltd. aluminum marking machine

- Perfect Laser Co. Ltd. color printer

- Perfect Laser Co. Ltd. dot peen marking machine

- Perfect Laser Co. Ltd. integration marking machine

- Desktop printer

- Compact printer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.