- Food industry

- Other Food Machinery

- Fish grader

- PERUZA limited liability company

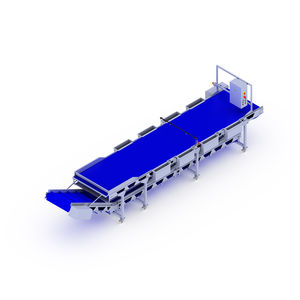

Fish grader rollerwith conveyor

Add to favorites

Compare this product

Characteristics

- Applications

- for fish

- Technology

- roller

- Other characteristics

- with conveyor

Description

Roller grading line for pelagic fish

Roller grading line is designed to calibrate fish by its thickness. The design is made for fresh small fish like sprats and Baltic herring species and similar ones like sardines, pilchards and anchovies.

Fish is supplied into receiving tank, where hopper- elevator lifts them up and drops onto distribution chute that later guides them onto rotating rollers. Tank is equipped with water level control system that helps to control permanent fish flow in any stage of work.

Roller grading unit performs fish grading into three grades + oversize grade. Grading unit rollers are deployed into V shape with option to adjust the gap between rollers on in and out

feed sides. Fish slides down the gap between rollers while the size of the gap is smaller than thickness of fish. When the fish size matches the gap size it falls through the roller gap and drops

in the determined grade.

Grades are separated and guided to cross – conveyors by easy moveable chutes. Fish from each grade is conveyed to the plastic bins is transported out with cross-conveyors. When the

plastic bins are full with fish, the line operator can separately stop any of cross-conveyors, change the bin and run the conveyor again.

Oversize grade is located at the end of roller unit.

Grading – A must for industrial processing of fish. Gentle grading of fish. Productivity up to 10 Tons per hour.

Main benefits:

Fast and safe grading

Less damage to fish

Easy adjustable grading system

Only 2 operators needed

VIDEO

Catalogs

No catalogs are available for this product.

See all of PERUZA limited liability company‘s catalogsOther PERUZA limited liability company products

Grading

Related Searches

- Food washing tunnel

- Vegetable food cleaning machine

- Gauging

- Fruit food cleaning machine

- Mechanical grader

- Gauging with conveyor

- Rinsing food washing tunnel

- Roller grading machine

- Fish grading machine

- Thawing station

- Belt grader

- Thawing machine

- Fish defrosting chamber

- Immersion food washing machine

- Thawing machine for the food industry

- Scale grader

- In-line thawing machine

- Fish thawing machine

- Immersion thawing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.