- Food industry

- Fish Processing

- Fish filleting machine

- PERUZA limited liability company

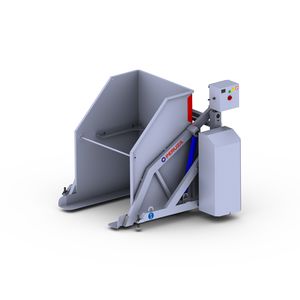

Fish filleting machine PASFF 110

Add to favorites

Compare this product

Characteristics

- Type

- fish

- Rate

200 p/min

Description

Equipment is designed for fresh pelagic fish processing. The nobbing section can create beheaded (H), degutted (G), tail cut (T) straight cut loins. With filleting unit it is possible to make “butterfly” type or single fillets or cut off belly and clean it with brushes.

PERUZA Automatic fish filleting machine – PASFF 110 is used for fish 9 – 14 cm, such as sprats, anchovies, capelin and other.

The beheading (H) and tail cut process (T) is made with rotary knives adjusted to the needed length of the final product, while degutting (G) is achieved with a vacuum suction unit that comes after cutting knives.

The processing machine can be adjusted for specific types and sizes of fish. The machine can be used for various species of fish if they do not exceed the pocket size of the machine.

Each fish must be placed head forward and belly first in each pocket to ensure the right cut. An optional, but suggested, vision system removes the requirement to orientate the fish belly first. Thus, enabling operators to work faster and ensuring less error percentage. This system is required if infeed of fish is done automatically.

Main benefits:

One machine replaces 4 - 5 manual processing specialists

3 times higher productivity than conventional pocket nobbing machines

Easy to operate

Catalogs

Other PERUZA limited liability company products

Fish processing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.