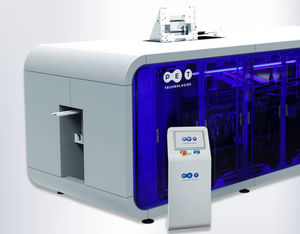

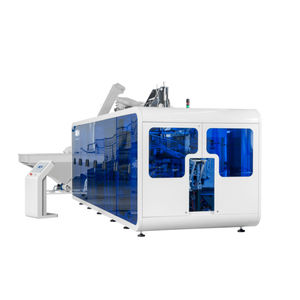

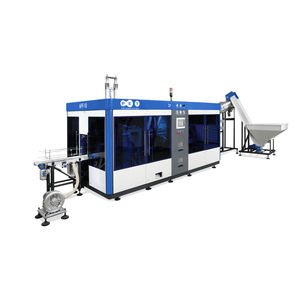

Stretch blow molding machine APF-Max 4HF for PETfor PET bottlesautomatic

Add to favorites

Compare this product

Characteristics

- Type

- stretch

- Treated material

- for PET

- Finished product

- for PET bottles

- Other characteristics

- automatic, electric, multi-cavity, for the food and beverage industry

- Hollow part volume

Min.: 0.2 l

(0.1 gal)Max.: 2 l

(0.5 gal)- Overall width

3,300 mm

(129.9 in)- Overall lenght

9,520 mm

(374.8 in)- Overall height

3,200 mm

(126 in)

Description

Innovative automatic blow molding machine for hot fill PET bottles production with output up to 5 000 bph. All-electric configuration. CE certificate and conformity to HACCP.

Output, bph - up to 5 000 bph

Quick change and Flexibility:

• - Option to increaser the output by installation of additional blow mold1 cavities

• - Modular blow mold System with separated mold cavities

• - Individual block of valves for each mold cavity with air recovery System

;

N IR heating and low total installed power: - «

• - Near infrared (NIR) heating System consumes less energy, its waves are more intensive

• - More efficient System than convectional IR

• - 8 heating modules with only 7 lamps

• - 108 mandrels in the heater

All-electric configuration:

• - 6 servo drives: in the mold closing unit, stretching unit, heater rotation, preform transfer to the blowing unit and bottle outfeed System

• - Pressure control in the blow mold

• - Preblow controlled via PLC

• - Automatic température régulation

User-Friendly concept and innovative design:

• - Streamline form and alternative coloring that meet corporate style

• - PLC that stands alone from the machine makes it easier to operate

• - Ail the communications are connected from the top of the machine

• - Electric cabinet backside

VIDEO

Catalogs

No catalogs are available for this product.

See all of PET Technologies‘s catalogsRelated Searches

- Blow moulding machine

- Bottle blow moulding machine

- Automatic blow molding machine

- Blow molding machine for the food industry

- Stretch blow moulding machine

- PET blow moulding machine

- PET bottle blow molding machine

- Electric blow molding machine

- Multi-cavity blow molding machine

- Semi-automatic blow molding machine

- 2-cavity blow moulding machine

- Blow molding machine for the beverage industry

- Blow molding machine for the automotive industry

- Blow mold

- Packaging blow mold

- PET bottle blow mold

- Fully-electric blow molding machine

- Multi-cavity blow mold

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.