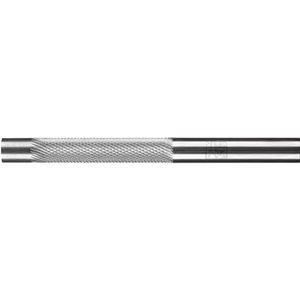

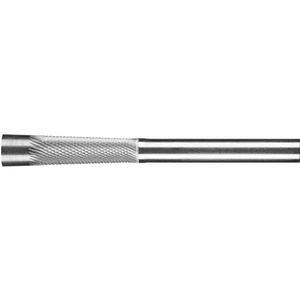

Solid milling cutter 1504 Z3 Plusburrdeburringtungsten carbide

Add to favorites

Compare this product

Characteristics

- Construction

- solid

- Type

- burr, deburring

- Material

- tungsten carbide

- Treated material

- for stainless steel, for cast iron, for non-ferrous metals

- Other characteristics

- cutting

- Diameter

3 mm, 6 mm

(0.12 in, 0.24 in)

Description

Cut 3 PLUS is cross cut and especially well-suited to machining of cast iron, steel, stainless steel (INOX), nickel-based alloys and titanium alloys. It is characterized by its high stock removal rate.

Tungsten carbide burrs for general applications are suitable for fine and coarse stock removal on the key materials used in industrial manufacturing. They provide a good stock removal rate and are not specific to a particular material.

Set 1504 – cut 3 PLUS – contains three small tungsten carbide burrs in the most common shapes and dimensions for applications in the workshop. The sturdy plastic box protects the tools from dirt and damage.

Advantages

Good stock removal rate through optimum matching of tungsten carbide, geometry, cut and available coating.

Long tool life.

The highly accurate concentricity enables impactfree working without creating chatter marks. This considerably reduces wear on the tool and tool drive.

High surface quality.

Materials that can be worked

Annealed cast iron

Black annealed cast iron (GTS, GJMB)

Case-hardened steels

Cast iron

Cast steel

Cobalt-based alloys

Grey/nodular cast iron (GG/GJL, GGG/GJS)

Hardened, heat-treated steels over 1.200 N/mm² (< 38 HRC)

High-temperature-resistant materials

Nickel-based alloys (e.g. Inconell and Hastelloy)

Stainless steel (INOX)

Steel

Steel, cast steel

Applications

Cutting out holes

Deburring

Leveling

Milling

Milling out

Surface work

Work on weld seams

Drive types

Flexible shaft drive

Robot

Stationary machines

Straight grinder

Tool machine

Catalogs

No catalogs are available for this product.

See all of PFERD‘s catalogsRelated Searches

- Milling tool

- Solid milling tool

- Steel milling tool

- Clamping milling cutter

- Metal milling tool

- Coated milling cutter

- Cast iron milling tool

- Cutting milling tool

- Hemispherical milling cutter

- High-performance milling tool

- Stainless steel milling tool

- Titanium milling tool

- Copper milling cutter

- Titanium alloy milling cutter

- Burr milling tool

- Side-and-face milling cutter

- Tungsten carbide milling tool

- Machine tool milling cutter

- Mini milling cutter

- Taper milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.