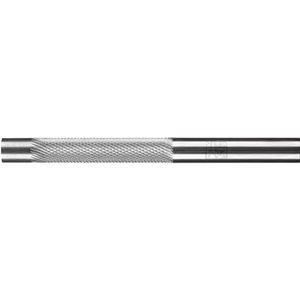

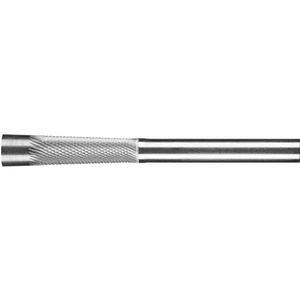

Burr 21101699 soliddeburringtungsten carbide

Add to favorites

Compare this product

Characteristics

- Construction

- solid

- Type

- burr, deburring

- Material

- tungsten carbide

- Treated material

- for stainless steel, for titanium, for titanium alloys, for non-ferrous metals

- Other characteristics

- cutting, machine tool

- Diameter

3 mm, 6 mm, 8 mm

(0.12 in, 0.24 in, 0.31 in)- Length

65 mm, 70 mm, 77 mm

(2.56 in, 2.76 in, 3.03 in)

Description

Tungsten carbide copy milling burrs by PFERD are the perfect tools for levelling elevations, such as weld seams. Thanks to the uncut area, the weld seam can be adjusted to the level of the surrounding surface without this being damaged. Copy milling burrs are used in particular in the repair of cutting and punching blades in tool and mould-making.

Advantages

Long tool life and high surface quality.

The uncut area provides optimum contour guidance and protects the workpiece against damage.

Reduced machining time.

Recommendations for use

For accurate contour guidance, copy milling burrs can be used with guide aids.

Observe the recommended rotational speeds.

To ensure costeffective use of burrs, use a higher rotational speed and cutting speed. Use burrs with a shank diameter of 6 mm with drives with a power output from 300 watts.

Materials that can be worked

Bronze

Case-hardened steels

Cast steel

Cobalt-based alloys

Hard aluminium alloys

Hardened, heat-treated steels over 1.200 N/mm² (< 38 HRC)

Hard non-ferrous metal

High-temperature-resistant materials

Nickel-based alloys (e.g. Inconell and Hastelloy)

Stainless steel (INOX)

Steel

Steel, cast steel

Applications

Cutting out holes

Deburring

Leveling

Milling

Milling out

Surface work

Work on weld seams

Catalogs

No catalogs are available for this product.

See all of PFERD‘s catalogsRelated Searches

- Milling tool

- Solid milling tool

- Steel milling tool

- Clamping milling cutter

- Metal milling tool

- Coated milling cutter

- Cast iron milling tool

- Cutting milling tool

- Hemispherical milling cutter

- High-performance milling tool

- Stainless steel milling tool

- Titanium milling cutter

- Copper milling cutter

- Titanium alloy milling cutter

- Burr milling tool

- Side-and-face milling cutter

- Tungsten carbide milling tool

- Machine tool milling cutter

- Mini milling cutter

- Taper milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.