- Metrology - Laboratory

- Metrology and Test Equipment

- Weight testing machine

- Pharma Technology

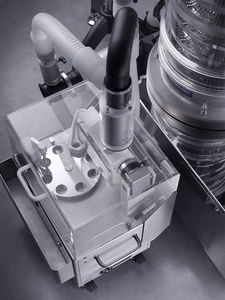

Tablet testing machine iTest Cmulti-parameterhardnessweight

Add to favorites

Compare this product

Characteristics

- Test type

- multi-parameter, hardness, weight

- Operating mode

- automatic

- Test material

- tablet, vacuum

- Technology

- mechanical

- Other characteristics

- stand-alone, process

Description

The “C” 4 parameters tester is a new generation of automatic tablet testing system for integrated process control (IPC). Intended for use as a stand-alone equipment with its own HMI or in combination with an upward conveying tablet deduster, the module offers premium analysis capabilities in testing tablets weight, thickness, hardness and length/diameter.

Key benefits

• Extremely quiet testing environment with no air turbulence - Very accurate measurement

• Complete separation between product and mechanical/electrical area to increase operator safety

• Tablets transfer by vacuum allowing less dust contamination in the tester area

• CFR 21 Part 11 compliant software

• Easy cleaning, validation and calibration

The core of the unit design is the strict separation of dust or tablet fragments from the production flow, resulting in a continuous manufacturing process. Tablets are sampled directly on the press and conveyed through a flexible hose to the tester via vacuum. The pinch valve placed at the input of the equipment, the optional H13 Hepa Filter and the light negative pressure are all elements to avoid environmental contamination and increase safety for operators. The entire test area is equipped with sealings. Sample tablets are tested for each parameter against pre-programmed recipes. The hardness broken ones are rejected in a Clip & Cut bag, while the non-destructed go in a separate Clip & Cut bag as witness.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Pharma Technology‘s catalogsRelated Searches

- Test machine

- Automatic test machine

- Universal test machine

- Precision test machine

- Test set

- Mechanical test machine

- Multi-parameter test machine

- Testing machine for the pharmaceutical industry

- Automatic test set

- Quality test machine

- Hardness test machine

- Stand-alone testing machine

- Process testing machine

- Tablet testing machine

- Weight test machine

- Process test system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.