Sorting and distribution system for the pharmaceutical industry automaticcapsuletablet

Add to favorites

Compare this product

Characteristics

- Application domain

- for the pharmaceutical industry

- Operational mode

- automatic

- Product applications

- capsule, tablet

Description

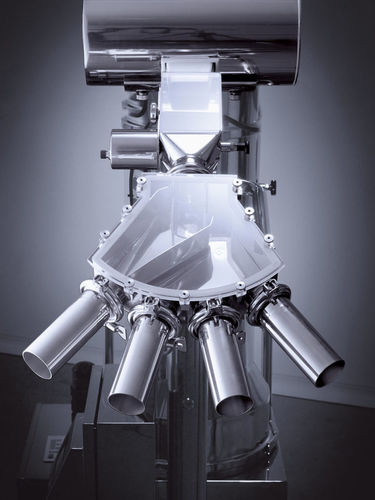

The automatic diverter is used to distribute the product into 2 or 4 drums according to the quantity of product produced, or alternatively according to the weight produced using scales.

Key benefits

• Extends manufacturing time without supervision

• Reduces manual operation in the production room

• Improves factory efficiency

• Reduces operator’s contact with the APIs

The distributor is highly flexible and, as the number of containers (up to 4) to be filled varies, so does the dropping height of the tablets and capsules. The diverter ensures less interference from the operators inside the production room, which reduces bi-cross contamination between operators and products. It can be connected to any deduster or polisher. The diverter can be equipped with a jam sensor to prevent downtime. This solution is available in “DT” Dust Tight, “C” Containment ≤0EB4, and “HC” High Containment ≤0EB5 washable versions.

Catalogs

No catalogs are available for this product.

See all of Pharma Technology‘s catalogsRelated Searches

- Rail conveyor

- Horizontal rail conveyor

- Sorting machine

- Automatic sorting machine

- Conveyor for the pharmaceutical industry

- Compact conveyor

- Vibrating conveyor

- Process sorting system

- Linear conveyor

- Sorter for the pharmaceutical industry

- Handling sorting system

- Sorting and distribution system

- Production hopper

- Capsule conveyor

- Automatic sorting and distribution system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.