- Building - Construction

- Production of building materials

- Stationary concrete batching plant

- Pi Makina Construction Machines

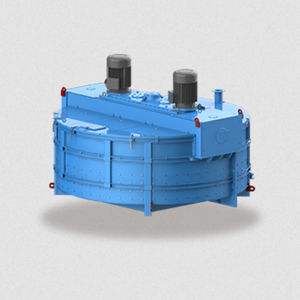

Stationary concrete batching plant Pi 100 BPspecial

Add to favorites

Compare this product

Characteristics

- Mobility

- stationary

- Other characteristics

- special

- Capacity

Min.: 90 m³/h

(3,178.32 ft³/h)Max.: 100 m³/h

(3,531.47 ft³/h)

Description

Pi 100BP concrete batching plant is a fixed concrete plant with belt and planetary mixer that can produce 90-100 m3 of concrete per hour. These plants, which are preferred in medium-sized projects where the plant will not be replaced, perform superiorly for many years. These concrete batching plants, designed with a belt aggregate conveying system, are also preferred for precast and concrete block practices with mold production lines thanks to the planetary mixer.

Safety equipment on batching plants, which by design provides easy transportation and easy installation, provides a safe working environment. At the same time, by virtue of its wide platforms, these are the concrete pants for which the maintenance of mixer and other components is the easiest.

Thanks to the software developed by Pi Makina used on the concrete plant, it is possible to obtain the entered prescription with low tolerance values. In addition, with its simple interface, many information such as the entire production, stock quantities, and customer records can be accessed from a single screen.

Outstanding Features

1 Installation and Operation

Minimum transport and installation time is required by dint of its superior design. With these features, the initial operating cost is very low.

2 Cost and Performance

With its erection in a short notice, it allows for immediate concrete pouring. It is remarkable with the sustainment of the same quality concrete pouring feature for years

Catalogs

No catalogs are available for this product.

See all of Pi Makina Construction Machines‘s catalogsOther Pi Makina Construction Machines products

Concrete Batching Plant

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.