- Building - Construction

- Production of building materials

- Mobile concrete batching plant

- Pi Makina Construction Machines

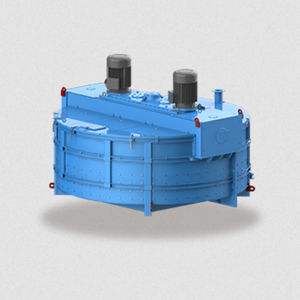

Mobile concrete batching plant Pi 30 FTcompactspecial

Add to favorites

Compare this product

Characteristics

- Mobility

- mobile

- Other characteristics

- compact, special

- Capacity

Max.: 30 m³/h

(1,059.44 ft³/h)Min.: 20 m³/h

(706.29 ft³/h)

Description

Pi 30 FT Mini Concrete Batching Plant, one of the innovations that Pi Makina has contributed to the sector, is capable of being installed in 1-2 hours and of starting concrete pouring immediately. It can be transported by a tow truck or an ordinary truck without a need for a mobile crane. This product, which does not entail any permission for concrete production, has a concrete capacity of 25-30 m3 per hour. In addition, it can mix all types of concrete smoothly and homogeneously with the 0.5 m3 planetary mixer installed thereon.

Pi Makina Mini Concrete batching Plants are preferred for short-term and small projects with their compact structure and fast assembly and disassembly feature.

Pi Cobasys software developed by Pi Makina as an automation system and created entirely with customer feedback is used. With Cobasys, the most advanced automation system on the market, any kind of report can be obtained and any adjustments related to the concrete batching plant can be easily made.

Outstanding Features

1 Installation and Operation

Minimum transport and installation time is required by dint of its superior design. With these features, the initial operating cost is very low.

2 Cost and Performance

With its erection in a short notice, it allows for immediate concrete pouring. It is remarkable with the sustainment of the same quality concrete pouring feature for years

3 Safety and Maintenance

Due to its simple structure, ease of maintenance and safety of employees with all safety equipment on it are prioritized.

4 Automation and Use

Thanks to the special automation system developed by Pi Makina, it offers quality and serial concrete production.

Catalogs

No catalogs are available for this product.

See all of Pi Makina Construction Machines‘s catalogsOther Pi Makina Construction Machines products

Concrete Batching Plant

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.