- Products

- Catalogs

- News & Trends

- Exhibitions

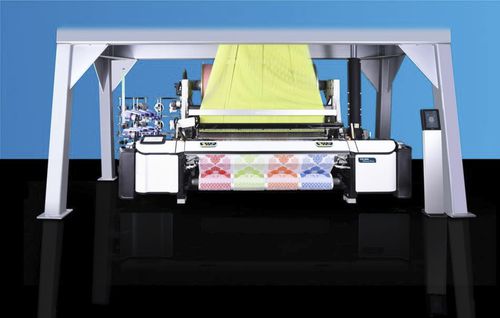

Rapier weaving machine Ultimax Terry

Add to favorites

Compare this product

Characteristics

- Other characteristics

- rapier

Description

When designing the new Ultimax Terry rapier machine, we focused on the following three aspects:

•Ultimate performance and high-quality output

•Readiness for the sustainability requirements of tomorrow

•The greatest ease of use, thanks to a maximum level of digitization, based on fully integrated sensors in almost every part of the machine

Ultimax Terry is the new benchmark for terry weaving with no limitations in design, while aiming at ultimate quality with maximum performance:

Stable pile formation,even at the highest speeds

Thanks to the unique pile motor set-up directly driving the cloth and backrest movement simultaneously, accurate pile formation is assured at highest speeds.

Optimum loop formation regardless of fabric design

The rigid yet extremely light construction ensures a highly dynamic behaviour, guaranteeing perfect loop formation for the most complicated terry designs, be it very light towels or heavy bathmats. This is by far the best pile compensation system ever!

No design limitations

The pile height-changing device makes it possible not only to change the group beat-up rate but also to weave structures such as waves. All set on the display!

This means that Ultimax Terry is - more than ever - a machine developed by design with our four design principles in mind: Sustainability Inside, Driven by Data, Smart Performance, and Intuitive Control.

Thanks to the high level of digitization and enabled by our digital platform PicConnect, the monitoring of both individual machines, as well as the entire weaving mill, will become much easier than before and will give you unprecedented control.

VIDEO

Catalogs

Ultimax Terry

13 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.