- Production Machines

- Forming Machine

- Pneumatic bending machine

- PIERANGELO SERVICE S.R.L.

Pneumatic bending machine ECT-1cablemechanical

Add to favorites

Compare this product

Characteristics

- Operation

- pneumatic

- Product handled

- cable

- Other characteristics

- mechanical

Description

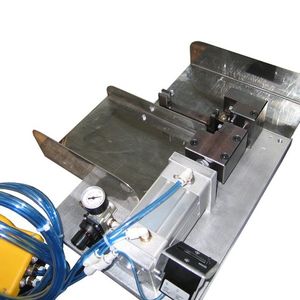

The equipment consists of an aluminum base on which are fixed:

– a mechanical lever system for bending the detail;

– a pneumatic cylinder, controlled by a two-hand safety device, for the movement of the lever;

– a template for housing the detail;

– a totalizer for counting the cycles performed;

The equipment takes about 2 sec. to carry out the work cycle.

– dimensions: cm. 90 x 40 x H20

– weight: 20 Kg

– pneumatic supply 5 bar

The operator inserts the part in the template seat, manually positions the support on the collar and inserts the pin in the large hole of the part.

At this point he presses the two buttons to start the work cycle; at the end of this he manually removes the machined piece and the pin inserted in it.

Catalogs

No catalogs are available for this product.

See all of PIERANGELO SERVICE S.R.L.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.