- Packing - Handling - Logistics

- Conveying

- Stainless steel conveyor belt

- PIERANGELO SERVICE S.R.L.

Stainless steel conveyor belt CF116toothedindustrial

Add to favorites

Compare this product

Characteristics

- Material

- stainless steel

- Pattern

- toothed

- Sector

- industrial

Description

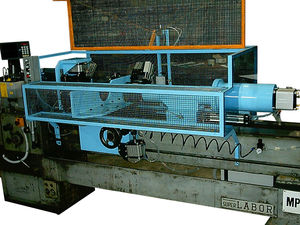

The conveyor has a useful length of about 2 meters and a width of 250 mm; it is equipped with a straight steel roller shutter chain for transporting the parts.

It consists of a stainless steel sheet structure with 4 legs on feet to support it, in which the following parts are applied:

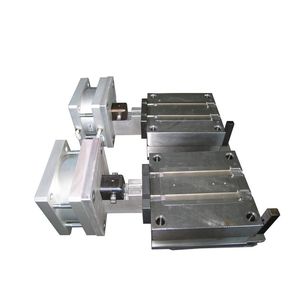

– a 190 mm wide straight steel roller shutter chain driven by a pair of toothed wheels that slides over polyzene strips,

– a gearmotor with inverter, to transmit forward / reverse motion

– a tank for collecting the drops of oil that fall on the toothed belts

– a pair of adjustable containment sides applied to the sides of the conveyor

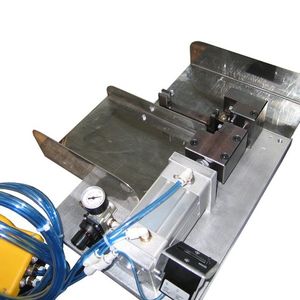

– a pusher system with sliding surface for moving the part from one conveyor to another (that of the machine)

– a series of thrust forks for the pusher group

– an electrical control panel with PLC with control push-button panel

– 230VAC power supply

– 5 bar pneumatic power supply the conveyor belt is placed side by side with the existing one in the deburring machine.

The operator places the detail on top of the straight conveyor chain, then presses a button to make it advance; the conveyor stops when the part reaches the position photocell in the pusher.

The operator can continue to load other parts on the conveyor by always using the same button even if the straight chain will slide under the parts as they lean against each other.

At the input of a certain signal from the deburring machine, the pusher will move a detail over the conveyor of the deburring machine: in this phase the straight chain of the new conveyor will remain stationary until the pushing cycle is completed.

Catalogs

No catalogs are available for this product.

See all of PIERANGELO SERVICE S.R.L.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.