- Industrial machines and equipment

- Furnace and Heat Treatments

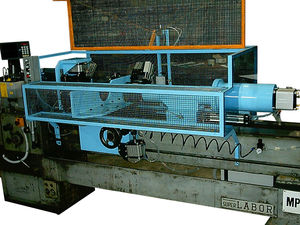

- Horizontal hardening machine

- PIERANGELO SERVICE S.R.L.

Horizontal hardening machine TM714induction

Add to favorites

Compare this product

Characteristics

- Options

- induction, horizontal

Description

The machine is used to automatically immerse the overheated pieces in the oil bath to perform rapid cooling for hardening.

This consists of a stainless steel structure to which the following parts are fixed:

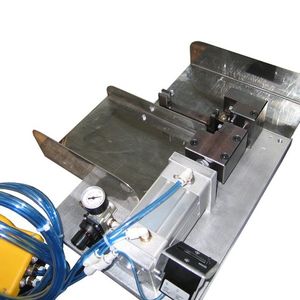

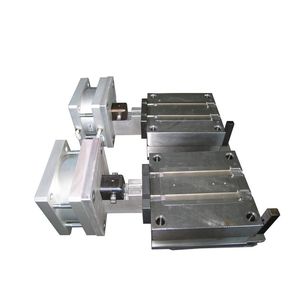

– a stainless steel tank with dimensions of 1000x600xH700 mm in which the oil is contained

– N.3 units for lifting and moving the pieces, each equipped with a support base with dimensions of 400×300 mm.

– a hood for conveying the ropes into the suction tube

– an electrical panel with operator panel and push-button panel on the machine for the control of each of the 3 lifting and translation units.

– dimensions 114 x 163 x H194 cm

– weight 350 Kg

– pneumatic power supply 5 bar

– 230VAC power supply

The operator places the pieces on one or more bases, and then activates the command to carry out the immersion cycle.

When the immersion time has elapsed, the pieces are automatically taken out of their respective units.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.