- Industrial machines and equipment

- Welding and Assembly

- Digital soldering station

- Pillarhouse International Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

PC-controllable soldering station PILOTdigital

Add to favorites

Compare this product

Characteristics

- Operating mode

- PC-controllable

- Digital/analog

- digital

Description

The all-new ultra-low-cost Pilot machine has been designed as an entry-level, handload, benchtop machine for small to medium batch manufacturers, combining high levels of production flexibility with economic running costs.

Offered with two universal, quick change tooling carriers, each one can be exchanged to optimise cycle time. Each carrier is capable of handling a board size up to 330mm x 250mm (13″ x 10″).

The Pilot incorporates, as standard, our patented Drop-Jet fluxer for quick, accurate flux deposition. An optional bottom side IR pre-heat is also available; this is particularly useful when processing multi-layer PCBs or using water-based flux types.

Although a low-cost system, the Pilot is offered with the ability to run the acclaimed, highly flexible Pillarhouse AP nozzle technology, together with our patented market leading 1.5mm Micro Nozzle. The process is enhanced by a localised hot Nitrogen environment at the point of soldering. An optional Nitrogen generator is built into the base of the unit and can be used to supply Nitrogen at the required levels, whilst acting as a machine stand.

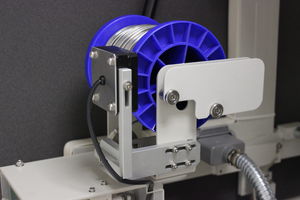

Designed for low maintenance, the Pilot offers a slide in/out solder bath design for ease of access. This, in conjunction with our proven impellor driven pump technology, makes a highly reliable, low maintenance system.

By carrying product over the flux, solder and optional pre-heat stations, the Pilot offers a light, highly accurate X, Y system.

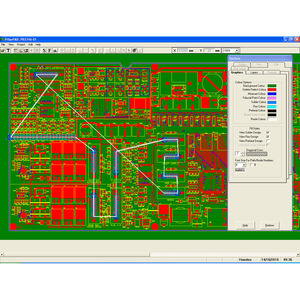

Programming is accessed through the world leading Pillarhouse ‘Point and Click’ PillarCOMMXLITE software package.

VIDEO

Other Pillarhouse International Ltd. products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.