- Industrial machines and equipment

- Welding and Assembly

- Rotary soldering machine

- Pillarhouse International Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

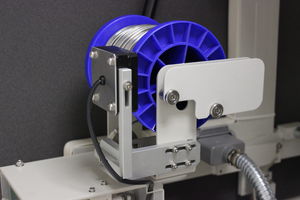

Rotary soldering machine QUADRONautomaticPLC-controlledfor PCB

Add to favorites

Compare this product

Characteristics

- Technique

- rotary

- Operating mode

- automatic, PLC-controlled

- Applications

- for PCB, for electronic components

- Other characteristics

- benchtop

Description

A versatile four station rotary bench top soldering machine, ideally suited for high or low volume production, the Quadron combines well proven pumped soldering techniques with advanced PLC-controlled movement technology.

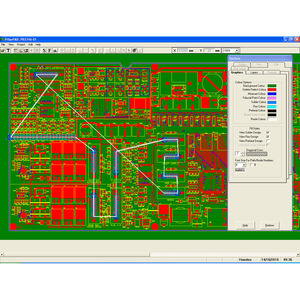

Much of its versatility is owed to the specially designed programming system which allows the user access to all fluxing and soldering parameters at any time. In addition, rapid product changeover is achieved quickly and easily through simple tooling design and program identification.

The machine is at home both processing coils/sub-assemblies/transformers or small PCBs, in either small or large batches. Cycle times as low as 5 seconds can be achieved.

Fluxing System

The flux is applied to the terminals via a crucible or sprung test probes, which is lifted from the bath to the component, this provides high quality and consistent repeatability. Flux application is of paramount importance, this is where the Quadron has an advantage, as it can control the application and avoid bobbin contamination by applying flux accurately. Excess flux and insulation residue is kept to a minimum by careful control of the dip height and immersion time, this being achieved through stepper drive motors. The Quadron can be supplied with either a fixed flux bath or self-contained recycling flux tank which helps reduce the evaporation of the flux thinners.

Other Pillarhouse International Ltd. products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.