- Products

- Catalogs

- News & Trends

- Exhibitions

Warehouse management (WMS) software ERPautomationcontrol

Add to favorites

Compare this product

Characteristics

- Function

- warehouse management (WMS), KPI analysis, automation, control, ERP

- Applications

- process

- Type

- real-time

Description

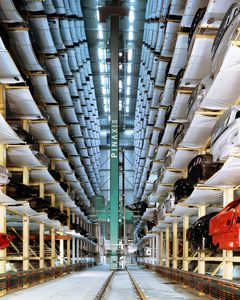

Running a warehouse or distribution center can at times seem like nothing short of a board game. However, with warehouse management software (WMS), you can orchestrate the entire operations with just one application, and it does in fact make everything run smooth and efficient. A WMS is an application software package that integrates into an enterprise resource planning (ERP) software application and a warehouse control software system (WCS) or a material flow controller (MFC) if you are running automation. However, the WCS /MFC can also do double duty if you are running a manual or hybrid / small, yet automated process as well. The WMS sits in the center of all equipment and other software components and dictates all work activities.

What are the Benefits of Using a WMS to Manage Your Warehouse or Distribution Operation?

Many small business operations may be able to forgo a WMS application for their operations. However, once a business starts to ship out a consistent amount of product each day, the chance for errors increase as well as operational costs. Many warehouse managers believe that a WMS system is for large, automated warehouses only. While most large facilities do use a WMS solution, many smaller manual operations can also benefit from a WMS as well. This starts becoming increasingly apparent with larger manual operations, facilities with a hybrid approach, and of course the smaller automated operations as well.

Accurate inventory is key when running a business. A WMS system checks on products that enter the warehouse and tracks each movement until it exits.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.