- Machine-tools

- Machining Center

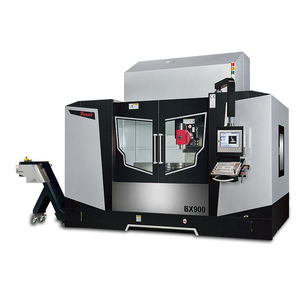

- 5-axis machining center

- PINNACLE Machine Tool Co., Ltd.

5-axis CNC machining center AX320 verticalwith rotary tilting table24 tools

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- with rotary tilting table

- Number of tool stations

- 24 tools, 40 tools, 30 tools

- Other characteristics

- direct-drive, rigid

- X travel

660 mm

(25.98 in)- Y travel

610 mm

(24.02 in)- Z travel

610 mm

(24.02 in)- Rotational speed

Min.: 12,000 rpm

(75,398 rad.min-1)Max.: 24,000 rpm

(150,796 rad.min-1)- Power

9 kW, 12 kW

(12.24 hp, 16.32 hp)- Work feed X-axis

30 m/min

- Work feed Y-axis

30 m/min

- Work feed Z-axis

24 m/min

- Table load capacity

150 kg

(331 lb)- Tool weight (max)

8 kg

(17.6 lb)- Weight

6,500 kg

(14,330.05 lb)- Overall length

2,660 mm

(104.7 in)- Overall width

2,230 mm

(87.8 in)- Overall height

2,560 mm

(100.8 in)

Description

The major structure parts are manufactured from high quality Meehanite cast iron, tempered for stress relief. The spindle head elevation employs a pneumatic type balance system to minimize the spindle head vibration during moving.

The 5-axis synchronized machining saves machining time reduces repetitive workpiece setup and error,while dramatically increasing machining and accuracy.

Pinnacle AX320/ AX450 are proven to be super machines for high efficiency and accuracy.

Features

A Axis Tilt 150° (-120°/+30°)

C Axis Rotary 360°

ISO40 Spindle Taper

X, Y & Z Axis Linear Way

Ruggedly Constructed Throughout to Provtde Lifetime Accuracy Year After Year

The major structural parts are manufactured form high quality Meehanite cast iron (GB 300), tempered for stress relief with hardness over 190HB.

Roller type linear ways on X, Y, Z axis increased stability.

X, Y, Z axis are transmitted with class C3, Ø40mm ball screws.

Hollow Ball Screw With Cooling System

Oil cooling through ball screws on X, Y, Z axis minimizes thermal deformation and backlash, while ensuring smooth motion during rapid traverse.

Pneumatic Balance System

The Z-axis is pneumatic counter-balanced via high response pneumatic cylinders. Plus an air reservoir tank to boost the balancing performance, ensuring fast and stable Z-axis movement, giving high surface finish.

Cooling System To Spindle

The spindle oil cooler permits the spindle to keep a constant temperature running and ensures long service life. It also provides high efficiency machining and high accuracy.

Rotary Table diameter Ø320 / Ø450mm

Rositioning accuracy, A/C-axis: 15"/10"

Repeatibility accuracy, A/C-axis: 10"/8"

VIDEO

Catalogs

Other PINNACLE Machine Tool Co., Ltd. products

5-AXIS Machining Center

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- High-performance CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- High-productivity CNC machining center

- Column type CNC machining center

- Cutting CNC machining center

- Milling machine

- CNC machining center with pallet changer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.