- Products

- Fish deheading machine

- Pisces Fish Machinery Inc.

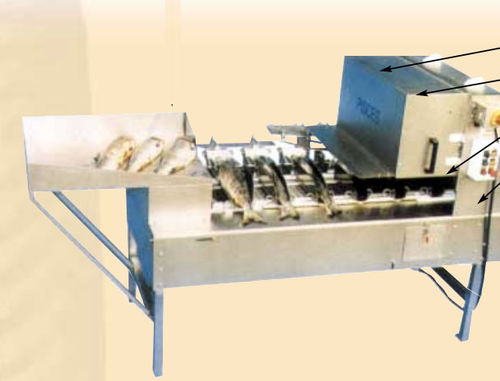

Fish heading machine HV 40

Add to favorites

Compare this product

Characteristics

- Applications

- for fish

- Capacity

35 p/min

Description

The HV-40 is a precision headcutting unit used to perform a highly accurate collarbone-off head cut. The HV-40 features a unique automated locating system that utilizes the collarbone for precise placement. This locating process allows for accurate head cuts, high levels of consistency and easy feeding.

High yields are ensured by two blades working in a modified "V" configuration to cut especially close to the collarbone without leaving any skull or collarbone on the fish. The HV-40 produces a fillet with smooth, precise edges eliminating the need for excessive trimming, thereby improving overall fillet yield.

Method of Operation

The operator places the fish in the moving trays, belly down and headfirst. The head is then pushed back until the collarbone catches in the correct location for an optimum-yield head cut. The head pushing method is such that the maximum amount of meat is retained on the body. Adjustable V-shaped blades then perform the head cut. These blades are able to accommodate different shapes of fish heads and bodies. After removal, the head is ejected from the side of the machine while the body is delivered from the end of the machine to the next operation station.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Pisces Fish Machinery Inc.‘s catalogsOther Pisces Fish Machinery Inc. products

Head Cutting Machines

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.