- Products

- Catalogs

- News & Trends

- Exhibitions

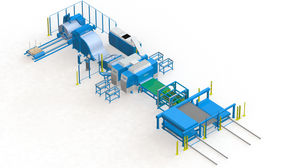

Automatic punching center PCC150-e TT HT CTWCNCelectricsheet metal

Add to favorites

Compare this product

Characteristics

- Control

- automatic, CNC

- Drive type

- electric

- Product handled

- sheet metal, press tool

- Associated function

- stacking, cut-to-width, cut-to-length

- Other characteristics

- coil-fed

Description

The PivaPunch Punching and Cutting Center produces blanks and punched blanks which are cut both to length and to width straight from the coil. Parts are produced according to the job orders created by the ERP system. This PivaPunch includes a press tool (type HT) for jobs like punching of large openings and fixed hole patterns, perforation and forming.

Efficiency

Punching the second nest and cutting to width of the first nest take place at the same time – in a single pass, straight from the coil.

In the punching station, two parts are punched at the same time using Thick Turret tools set in two Tool cassettes.

Dedicated press tools can be used for perforation, standard hole patterns, large holes and for forming.

The material utilization is the highest possible. No scrap between the parts in X-direction and parts are nested side by side in the optimum way.

Flexibility

Coils of standard width with raw edges from the steel mill are used. Part dimensions, both the length and the width - and the hole patterns are programmable. Also pre-cut blanks for turrets can be produced on Just In Time basis.

Quality of blanks

All four sides of blanks are cut in shears, each with one stroke, instead of having been nibbled resulting in good edge quality without tolerance peaks.

Sheet thickness: 0,5 mm - 2 mm

Working length: inf. strip feeding, 1000 mm - 5000 mm

Working width: 120 mm - 1525 mm

Material: mild steel, stainless steel, hot-dip galvanized steel, electrogalvanized steel, plastic coated steel, pre-painted steel, aluminium

VIDEO

Catalogs

No catalogs are available for this product.

See all of Pivatic‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.