Optical profilometer ProfilControl DualVisionindustrialcompactnon-contact

Add to favorites

Compare this product

Characteristics

- Technology

- optical

- Domain

- industrial

- Configuration

- compact

- Other characteristics

- non-contact

Description

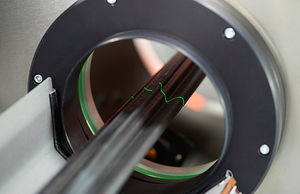

A milestone in automated quality control of profiles, tubes, pipes and cables!

This compact system not only combines surface inspection and dimension measurement. It can also perform several different, highly challenging measuring and inspection tasks at the same time. Measuring performance at its best – combined with highest user friendliness.

Industry-specific products

Sealing profiles for car bodies, hoods, doors

Hoses for brakes, A/C, cooling systems

Profiles for windshield wipers

Trims and cover fillets

Metal profiles for car bodies and drive trains

Window shaft seals

Edge protection profiles

and many more

Your benefits at a glance

Reduces production costs

Increases product quality and output

Automated and more efficient processes

Increases process stability and repeatability

Interlinking of Big Data - Ready for Industry 4.0

Saves resources and investment capital

Scalable technology – Made in Germany

Detectable defects and deviations

Specially developed lighting elements ensure that the measuring field is extremely homogeneously lit, allowing the camera sensors to even capture and process invisible and difficult-to-detect irregularities and defects – for example, specks, pores, scratches, blisters, fissures or grooves.

Catalogs

No catalogs are available for this product.

See all of PIXARGUS GmbH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.