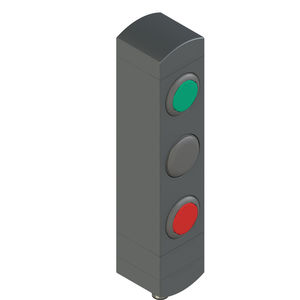

6-button pendant station BN 5-buttonautomationindustrial

Add to favorites

Compare this product

Characteristics

- Number of buttons

- 5-button, 6-button

- Other characteristics

- industrial, control, automation

Description

The evolution of communication technology opened the doors to new solutions in the industrial automation field. One of these solutions is IO-Link, an open communication standard for sensors and actuators, defined by the PROFIBUS User Organization (PI).

IO-Link can be used for the point-to-point connection of sensors and actuators to the control system; fast and reliable data transmission guaranteed.

In this cutting-edge technological field, the BN series control device unit stands out as versatile, state-of-the-art device. By connecting to the IO-Link master, the BN control device unit can exchange essential data on the surrounding environment, providing detailed information on the different operating phases.

The data sent includes the state of the buttons and different device types, the LED state, the supply voltage, the device utilisation time and temperature.

One key feature of the BN series IO-Link control device unit is its ability to detect any out-of-range values in the monitored data. The system can detect any anomalies or potential risks so that the operators can quickly adopt the necessary measures.

What’s more, with IO-Link technology all the data on the device can be displayed in real time, which means immediate monitoring and precise performance.

Catalogs

BN series control device units

12 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Control foot switch

- Single pedal foot switch

- Electric foot switch

- Push-button box

- IP65 control station box

- Emergency stop push-button box

- 2 pedals foot switch

- Control knob

- Signaling indicator light

- Industrial push-button box

- 3-button push-button box

- IP65 foot switch

- Elevator pendant station

- 6-button push-button box

- Control push-button box

- 8-button push-button box

- 5-button pendant station

- 7-button pendant station

- Lifting pendant station

- Timer module

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.