Plasma surface treatment machine for film

Add to favorites

Compare this product

Characteristics

- Type

- plasma

- Other characteristics

- for film

Description

Openair® plasma is a simple and environmentally friendly method of cleaning aluminum surfaces. Composite films are used in particular in the production of beverage and food packaging to keep the packaging gas-tight. Here, the films are lamintated with the aluminium foil (aluminum layer). The material is additionally coated with PE so the aluminum does not come directly in contact with the contents.

Removal of adherent rolling oils prior to lamination of composite films

The aluminum in the film system is pretreated with Openair® plasma to ensure a reliable bond with the PE film. All organic substances, such as rolling oils, are split on the material surface during plasma cleaning and removed.

The annealing procedure still widely used in the industry is time- and energy-consuming as compared to Openair® plasma treatment. By contrast, with the Openair® procedure, the plasma system is integrated inline into the existing overall process. This makes plasma pretreatment especially cost-efficient.

Openair® plasma systems for the pretreatment of aluminum foil – advantages and properties:

Energy-saving, inexpensive and environmentally friendly

No change in the foil’s mechanical properties

Usual treatment width per nozzle = 10 mm (100 nozzles/m)

Usual treatment width of the foil = 2.20 m

Two-sided foil treatment possible

Inline integration of the plasma system before the coil winder (no process interruption)

Catalogs

No catalogs are available for this product.

See all of Plasmatreat‘s catalogsRelated Searches

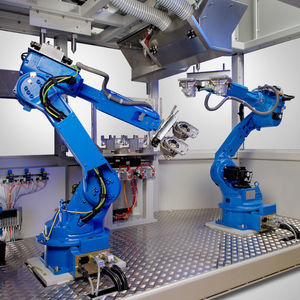

- Industrial robot

- Articulated robot

- 6-axis robot

- Handling robot

- Compact robot

- Cleaning atomizing nozzle

- Plastic nozzle

- Surface treatment machine

- Hollow-cone nozzle

- PP nozzle

- Plasma surface treatment machine

- Rotary atomizing nozzle

- Surface treatment robot

- Glue nozzle

- Aluminium nozzle

- Surface treatment machine for the printing industry

- Plasma generator

- Surface treatment nozzle

- Outlet nozzle

- Rubber nozzle

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.