Laboratory plasma generator AS400

Add to favorites

Compare this product

Characteristics

- Type

- laboratory

Description

The Plasmatreater AS400 offers optimal conditions for laboratory work. This plasma laboratory system is ideal for determining parameters for plasma cleaning, plasma activation and nano-coating (plasma polymerization).

All plasma parameters required for the specific process and the desired material properties are evaluated analogous to standard production conditions and in order to be reproducible. Factors, such as speed or distance of plasma nozzles, are determined by computer and recorded.

Optionally, the AS400 can be extended to include, for example, a thread winder for experiments in the field of textiles or a roller system for experiments with tape stock such as woven goods or films.

Areas of application:

Surface treatment prior to bonding, painting or printing

Ultrafine cleaning

Activation of polymer surfaces

Generation of hydrophobic polymer layers on the surface (corrosion protection, scratch-resistant)

Generation of hydrophilic polymer layers on the surface (adhesion improvement)

Generation of barrier layers

Catalogs

No catalogs are available for this product.

See all of Plasmatreat‘s catalogsRelated Searches

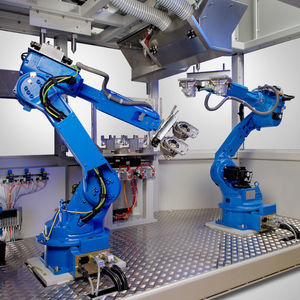

- Industrial robot

- Articulated robot

- 6-axis robot

- Handling robot

- Compact robot

- Cleaning atomizing nozzle

- Plastic nozzle

- Surface treatment machine

- Hollow-cone nozzle

- PP nozzle

- Plasma surface treatment machine

- Rotary atomizing nozzle

- Surface treatment robot

- Glue nozzle

- Aluminium nozzle

- Surface treatment machine for the printing industry

- Plasma generator

- Surface treatment nozzle

- Outlet nozzle

- Rubber nozzle

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.