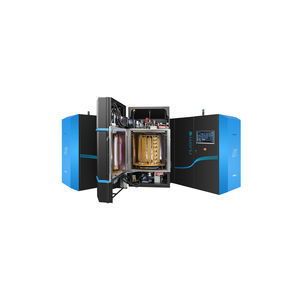

PVD deposition machine PL1011 G4

Add to favorites

Compare this product

Characteristics

- Method

- PVD

Description

he PL1011 G4 represents the next generation of a robust PVD coating unit from PLATIT for customers who seek a combination of process reliability and high-quality coatings at a low cost per tool. Its new design speaks for changes and modernization: the simpler construction enables better service; the new technological features such as the Plasma-Nitriding and Double-Pulsed options improve the coating properties and process for various applications.

As the backbone of every high-volume coating center, PL1011 G4 combines maximum production availability with a user-friendly interface and an efficient maintenance concept. It’s equipped with four Planar cathodes utilizing the latest ARC technology for the deposition of all PLATIT standard coatings in consistently high quality.

4 x Planar cathode using ARC technology for depositing

LGD® (Lateral Glow Discharge)

Plasma etching with argon, glow discharge

Metal ion etching (Ti, Cr)

Max. coating volume [mm]: ø715 x H805

Max. coating height with defined coating thickness: 711mm

Max. load: 400kg

3-4 batches/day

1 to 12 axes

PLATIT SmartSoftware (PC and PLC system) with touch screen

Statistics and help function via user interface

Data recording and real-time display of process parameters and flow

Manual and automatic process control

Remote diagnostics and maintenance

Newly designed recipe editor

Footprint [mm]: W4000 x D2250 x H2350

Footprint Double-Pulsed option [mm]: W4700 x D2250 x H2350

VIDEO

Catalogs

No catalogs are available for this product.

See all of PLATIT AG‘s catalogsRelated Searches

- Automatic washing machine

- Water washing machine

- Industrial washing machine

- Stainless steel washing machine

- Process washing machine

- Ultrasonic cleaning system

- Parts washing machine

- Compact washing machine

- Washing machine with rinsing

- PVD deposition machine

- Washing machine with dryer

- Surface treatment cleaning system

- Custom washing machine

- High-pressure washing machine

- Continuous washing machine

- Environmentally friendly washing machine

- Metal part cleaning system

- High-performance washing machine

- Mold washing machine

- Vacuum cleaning system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.