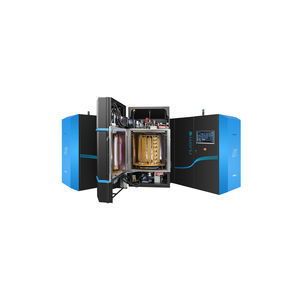

PVD deposition machine PL711

Add to favorites

Compare this product

Characteristics

- Method

- PVD

Description

The PL711 is a compact sputter coating unit based on HiPIMS technology (High Power Impulse Magnetron Sputtering). It has two planar HiPIMS cathodes and allows to deposit selected nitride and carbon coatings (DLC2, DLC3) using highly productive processes.

The dense plasma with high ionization in the carousel produces homogeneous coatings and a high deposition rate. Coatings from PL711 provide excellent smooth surfaces while maintaining high density, hardness and outstanding adhesion.

Technology

A PL711 coating unit uses 2 planar sputtering cathodes with HiPIMS technology.

Etching processes

Several etching technologies can be used in the PLATIT PL711 coating unit, offering various advantages:

LGD® (Lateral Glow Discharge)

Plasma etching with argon, glow discharge

Metal ion etching (Ti, Cr)

Deposition types

Sputter nitride coatings

Reactive and non-reactive processes

Targets: Ti, Cr

Coating temperature up to 350°C

Sputter Cr and PECVD a-C:H:Si

DLC2 (PECVD coating)

Targets: Cr

Coating temperature 180-220°C

Load and cycle times

Coating volume: max. ø600 x H805mm

Coating height with defined coating thickness: max. 500mm

Load: max. 250kg, higher weight upon request

Batches/day: 2

Modular carousel systems

3 axes or

6 axes or

9 axes

Software

PLATIT SmartSoftware (PC and PLC system)

Easy operation and maintenance

Modern user interface with menu navigation on touch screen

Real-time process visualization incl. data recording and data management

Manual and automatic process control

Remote diagnosis and maintenance possible

Catalogs

Related Searches

- Automatic washing machine

- Water washing machine

- Industrial washing machine

- Stainless steel washing machine

- Process washing machine

- Ultrasonic cleaning system

- Parts washing machine

- Compact washing machine

- Washing machine with rinsing

- PVD deposition machine

- Washing machine with dryer

- Surface treatment cleaning system

- Custom washing machine

- High-pressure washing machine

- Continuous washing machine

- Environmentally friendly washing machine

- Metal part cleaning system

- High-performance washing machine

- Mold washing machine

- Vacuum cleaning system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.