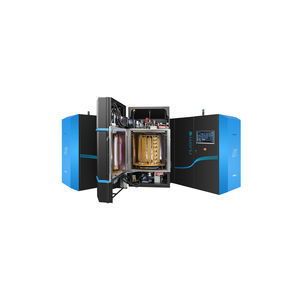

PVD deposition machine PL2011

Add to favorites

Compare this product

Characteristics

- Method

- PVD

Description

With the PLATIT PL2011, we offer you an arc coating unit capable of handling particularly large batch volumes. A specially designed carousel with 5 different configurations allows maximum load flexibility while maintaining coating quality. This unit can coat either a large number of tools with either small or large diameters or mixed loads in one batch. PL2011 is designed for PVD coating of tools up to a diameter of 1423mm. The carousel can be loaded up to 1800kg.

PL2011 is based on the double-pulsed function of PL1011G4. This increases the coating speed by 30% compared to the standard process. Pulsed cathodes allow smoother PVD coatings due to improved arc distribution. The use of arc power supplies on alloyed targets improves deposition rate and coating distribution, ensures more uniform target erosion, and extends the life of the target material.

Technology

6 planar arc cathodes, 4 of which have pulsed arc power supplies to allow pulsing of the cathodes

Etching processes

The PLATIT PL2011 coating unit allows the use of three different etching processes:

LGD® (Lateral Glow Discharge) with 2 cathodes with shutter and 2 cathodes acting as anodes

Plasma etching with argon, glow discharge

Metal ion etching (Ti, Cr)

The PVD coating unit has 2 doors, providing perfect access to the chamber. This simplifies machine and cathode maintenance and speeds up loading and unloading: While the finished batch is removed through one door, the next batch can be loaded through the other door.

In addition, the always correct alignment of the carousel carriage by means of a track system facilitates the loading and unloading of substrates up to max. 1800kg.

Catalogs

No catalogs are available for this product.

See all of PLATIT AG‘s catalogsRelated Searches

- Automatic washing machine

- Water washing machine

- Industrial washing machine

- Stainless steel washing machine

- Process washing machine

- Ultrasonic cleaning system

- Parts washing machine

- Compact washing machine

- Washing machine with rinsing

- PVD deposition machine

- Washing machine with dryer

- Surface treatment cleaning system

- Custom washing machine

- High-pressure washing machine

- Continuous washing machine

- Environmentally friendly washing machine

- Metal part cleaning system

- High-performance washing machine

- Mold washing machine

- Vacuum cleaning system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.