Cosmetic cream filler and capper RTE2Upneumaticfor high-viscosity productsautomatic

Add to favorites

Compare this product

Characteristics

- Type

- pneumatic

- Product applications

- for high-viscosity products, cosmetic cream

- Operating mode

- automatic, motorized

Description

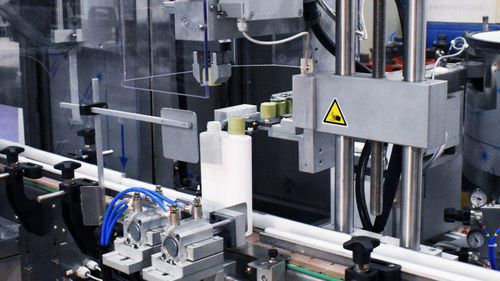

Filling and capping line with pick & place.

Solution for creamy substances composed of:

• motorized loading plate;

• conveyor belt;

• hopper with 20 l capacity, suction pipe with bottom valve for product transfer directly from the storage tank;

• 2 pneumatic devices for blocking the jars in the filling station and in the capping station;

• filling station with 2 dosage nozzles, dosage range from 50 to 1000 cc.

• pick & place system for automatic cap positioning;

• capping station for closing screw caps.

Production: 1000 pcs/h.

Machine management via PLC and touch screen panel.

• Ideal solution for : cosmetic liquids and creams-dense and semi-dense solutions.

VIDEO

Catalogs

No catalogs are available for this product.

See all of PMR System Group‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other PMR System Group products

MONOBLOCKS AND CUSTOM LINES -COSMETICS

Related Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Bottle filler

- Volumetric filler

- Bottle labeling machine

- Semi-automatic filler

- Multi-head filler

- Filler for the chemical industry

- Filler for the pharmaceutical industry

- Side labelling machine

- Labeling machine for the food industry

- PLC-controlled filler

- Filler for the cosmetics industry

- Labeler for the cosmetics industry

- Labeller for the pharmaceutical industry

- Top labelling machine

- Container filler

- Automatic capper

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.