- Machine-tools

- Cutting Tool

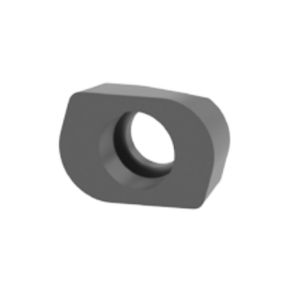

- Milling cutting insert

- POKOLM Frästechnik GmbH & Co. KG

Machining indexable cutting insert M40 PVSTmillingcarbidefor stainless steel

Add to favorites

Compare this product

Characteristics

- Function

- machining, milling

- Material

- carbide

- Treated material

- for stainless steel

- Other characteristics

- coated

Description

BRIGHT PROSPECTS...

M40 and PVST are features for efficient machining of stainless-, acid- and heat-resistant

materials. Extremely tough and high-temperatureresistant carbide in combination with our modified AlTiNcoating layer reduce built-up edges, increase thermal stability and reduce friction between cutting edge and material at the same time. This results in a maximum process reliability, even with highest possible chip volume and results in lower costs per component.

TECHNICAL INFORMATION

Due to the reduced arc of contact, when machining vertical moulds, less cutting forces influence milling cutters, inserts and machine spindle. These following graphics explain the kind of geometry influence to those cutting forces. One further element is the reduced power consumption of the machine, which allows more careful treatment of the machine

Comparing different arcs of contact for increasing cutting depths (ap up to ap 3) illustrate the reason of better running smoothness. As soon as the ap-value has exceeded the size of our QUADWORX®-insert’s minor cutting edge (ap 3), the milling cutter gets a side clearance and thus it is cutting free and radial forces for milling cutter, inserts and machine spindle are decisively reduced.

Catalogs

No catalogs are available for this product.

See all of POKOLM Frästechnik GmbH & Co. KG‘s catalogsOther POKOLM Frästechnik GmbH & Co. KG products

Indexable Inserts

Related Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- Insert milling tool

- End mill milling tool

- Coated milling cutter

- Cast iron milling tool

- Indexable cutting insert

- General purpose drill bit

- Cutting milling tool

- Hemispherical milling cutter

- Solid carbide milling tool

- Face milling tool

- Roughing milling tool

- Shell-end milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.