- Machine-tools

- Cutting Tool

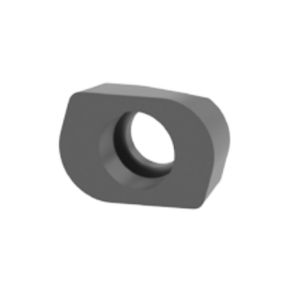

- Milling cutting insert

- POKOLM Frästechnik GmbH & Co. KG

Milling indexable cutting insert SLOTWORX® Lcarbidecoatedfor face milling cutter

Add to favorites

Compare this product

Characteristics

- Function

- milling

- Material

- carbide

- Other characteristics

- coated, for face milling cutter

Description

square shoulder face milling cutters for universal applications - with special inserts for high feed cutting

Slotworx® from S to L offers to you a complete range of square shoulder face milling- and slotting end mills for universal applications: roughing and finishing of steel, cast iron, aluminium, graphite, plastics as well as hardened materials and for machining stainless steel, high-temperaturealloys and superalloys.

The Slotworx®-range is available with threaded shanks, plain shanks and clamping flats, shell type milling cutters and with our patent protected DuoPlug®-system for highest

concentricity and maximum rigidity. These threaded shank milling cutter bodies in connection with our dense-antivibration adapters are extremely applicable for finishing operations, in connection with Solid carbide adapters for roughing operations in deep cavities. Exceptionally precision-manufactured cutter bodies guarantee excellent

milling results.

Optimum coolant supply direct to the cutting edges avoids any chip built-up on the insert’s cutting face and it ensures maximum process reliability and secure chip removal, also in difficult materials.

Small, but big in capability, the Slotworx®-“S” range features itself through exceptional easy cutting. The tools of the Slotworx®-“M“ series with the widest range of rotating inserts are multifunctional for all applications. The specially developed inserts even make tools in this size ideal as high feed-rate end mills for HighFeed hard machining all materials up to 60+2 HRC. The adapted cutting face geometry of these cutting materials also guarantees extremely long service lives with quiet running characteristics at the same time.

Catalogs

No catalogs are available for this product.

See all of POKOLM Frästechnik GmbH & Co. KG‘s catalogsOther POKOLM Frästechnik GmbH & Co. KG products

Indexable Inserts

Related Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- Insert milling tool

- End mill milling tool

- Coated milling cutter

- Cast iron milling tool

- Indexable cutting insert

- General purpose drill bit

- Cutting milling tool

- Hemispherical milling cutter

- Solid carbide milling tool

- Face milling tool

- Roughing milling tool

- Shell-end milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.