- Machine-tools

- Machine Tool Accessory

- HSK tool holder

- POKOLM Frästechnik GmbH & Co. KG

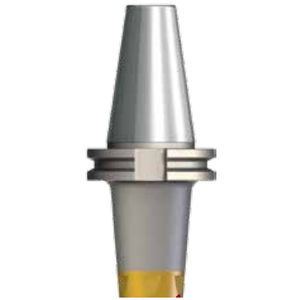

HSK tool holder HSK 100 Form ADINtaper shankmilling

Add to favorites

Compare this product

Characteristics

- Machine mount

- HSK, DIN

- Clamping method

- taper shank

- Application

- milling

- Other characteristics

- balanced, cutting, solid carbide

- Clamping range

Min.: 6 mm

(0.24 in)Max.: 16 mm

(0.63 in)- Rotational speed

12,000 rpm

(75,398 rad.min-1)

Description

COOLCAP® – Mills and media-optimised cooling arbors for Solid Carbide End Mills

The COOLCAP® arbors made by Pokolm Frästechnik are deemed the new, optimal system for effective cooling of Solid Carbide End Mills.Pokolm-Coolcap

The manufacturer from eastern Westphalia, famous for innovative solutions, designed the COOLCAP® arbors so that both the volume flow and the discharge velocity are perfectly matched to the various milling diameters and are adapted to the various cooling media at the same time. This especially effective direct cooling through a curtain jet enables higher speeds. Moreover, chips are securely removed from the cutting zone. The best possible lubrication action in the cutting zone additionally guarantees a high surface quality. That makes the entire milling process faster, more efficient and safer – indispensable prerequisites for optimised machining performance.

COOLCAP® arbors are available with machine-side connections HSK 63 – Type A and SK 40 – DIN 69 871 AD respectively for Solid Carbide End Mills in the diameters 6, 8, 10, 12 and 16 mm. Replaceable caps for different cooling media such as air/MLQ or emulsion round off the cooling arbor system.

HSK 100 Form A

for Weldon shank | CoolCap®

• Hollow taper shank arbors according to DIN69893 form A, maximum precision

• fine balanced to G 6.3 gmm at 12,000 rpm

• with internal coolant supply and bore hole for the coolant supply tube

• effective direct cooling for solid carbide end mills because of a ring-shaped

cooling jet

• increased process reliability when using milling cutter bodies with indexable

inserts in connection with extensions by removing the chips from the cutting area

Catalogs

Arbor and Adapter Systems

163 Pages

Other POKOLM Frästechnik GmbH & Co. KG products

Hollow taper shanks HSK

Related Searches

- Chuck

- Milling chuck

- Collet chuck

- Drilling chuck

- HSK chuck

- DIN chuck

- Milling tool holder

- High-precision chuck

- Morse taper chuck

- HSK tool holder

- Drilling tool holder

- Morse taper shank tool holder

- BT chuck

- DIN tool holder

- Taper shank chuck

- High-precision tool holder

- Balanced chuck

- CNC machine chuck

- Taper shank tool holder

- Cutting tool holder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.