- Hydraulics - Pneumatics

- Filter and Separator

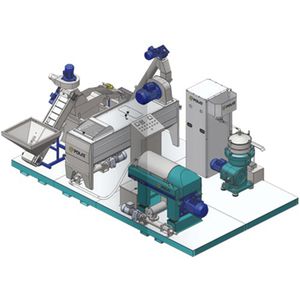

- Olive oil decanter

- POLAT MAKINA SANAYI VE TICARET A.S.

Olive oil decanter PMS 570 / PX 160for mineral oilcentrifugalhorizontal

Add to favorites

Compare this product

Characteristics

- Applications

- for olive oil, for mineral oil

- Type

- centrifugal

- Orientation

- horizontal

Description

The drummer transfer to the 3000 r/m the centrifugal forges keep the oil production at the maximum level and thus, the system separates the crude paste, water and the olive oil from each other according their specific gravity. The paste carried by the paste pump enters the decanter drum together with the water coming from the flowmetre at 35-45 C.The water is carried out to the lower unit of the decanter from the entrance channel behind the drum and then it is sent to the vibrated sieve near the decanter.The oil within the drum is specially designed and it is taken out of the drum by burners located opposite to each other. The oil entering the lower unit of the decanter helps to discharge the paste out of the system by creating a transfer differention throughvibration. Screw coils are covered with 2,5 mm think tungsten carbide of 60-65 Rockwell. The aim here is to minimise the abrasion which may occur in time. All surfaces and the equipment the olive paste touches as it enters in to the decanter are made out of inox materials according to the food regulations.

Catalogs

No catalogs are available for this product.

See all of POLAT MAKINA SANAYI VE TICARET A.S. ‘s catalogsOther POLAT MAKINA SANAYI VE TICARET A.S. products

Decanters

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.