- Hydraulics - Pneumatics

- Filter and Separator

- Industrial decanter

- POLAT MAKINA SANAYI VE TICARET A.S.

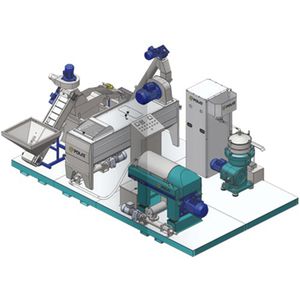

Industrial decanter PMS 350 / R 20centrifugalhorizontal

Add to favorites

Compare this product

Characteristics

- Applications

- industrial

- Type

- centrifugal

- Orientation

- horizontal

Description

Product is delivered into the decanter’s drum by the mono-pump. Here, as the results of the applied G forces, the 12% solid and 88% liquid contents in the products are being separated from each other in the superb quality. Liquid content is delivered to the decanter’s lower container through rear channel and then, discharged from there out of the system. The solid content is proceeded to the front side of the decanter. From that point, it is taken into the stock tank. Gearbox assembled at the front part of the drum provides the discharge of the solid content out of the system, through creating a certain rotation difference between the drum and the internal spiral. Spiral coils have been plated with the tungsten carbide, hardness of which is 60-65 Rockwell. The reason for this application is to decrease the wearing to the minimum level, which might be occurred in time. All of the surfaces and equipments, with which the product has contacts following to its entering into the decanter, are produced from the inox material in compliance with the food codex. The main chassis, which provides the bearing for the decanter’s drum, has been manufactured from the St-37 steel.

Catalogs

No catalogs are available for this product.

See all of POLAT MAKINA SANAYI VE TICARET A.S. ‘s catalogsOther POLAT MAKINA SANAYI VE TICARET A.S. products

Decanters

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.