- Industrial machines and equipment

- Welding and Assembly

- Thermal insulation tape

- Polyfluor Plastics bv

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

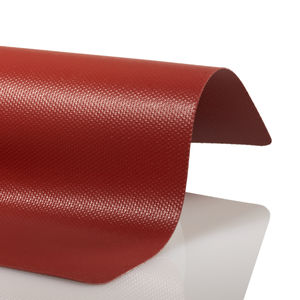

Thermal insulation tape Type BP sticPTFEsiliconereinforced

Add to favorites

Compare this product

Characteristics

- Function

- thermal insulation

- Material

- silicone, PTFE

- Other characteristics

- high temperature-resistant, self-adhesive, reinforced

Description

Type BP stic is similar to our type BP, but designed with a self-adhesive silicone layer on one side. This adhesive layer is covered with a release liner. The base material is a glass fibre impregnated with PTFE. The standard silicone adhesive layer is resistant up to a maximum temperature of +250°C. On request, type BP stic is available with acrylic adhesive layer for applications requiring a higher adhesion. This acrylic adhesive can be used up to +120°C. PTFE glass fibre is used in many applications. For example in industrial processes requiring non-stick properties. An important application in the packing industry is the use in heat-seal machines, but also for the coating of molds and (sliding) gutters. Standard packing unit of type BP stic are rolls of 30 mtr, in various widths. Other lengths are available on request. The most common thicknesses are 0,08 mm/0,11 mm/0,12 mm/0,21 mm. The standard colour of PTFE glass fibre is light brown. Other colours available on request. Our sales engineers are at your service when you want to determine the right formula for your application.

Key properties PTFE glass fibre

Excellent chemical resistance

Good anti-stick properties

Easy to clean

Low friction coefficient from 0.04 to 0.10 (depending on load, transport speed and temperature)

Excellent electrical, insulation and dielectric properties

Foods suitable (USFDA)

More information?

Please contact our sales engineers if you require more information, an inquiry or to evaluate samples. Or download our technical data sheets.

Catalogs

Other Polyfluor Plastics bv products

PTFE glass fibre belts&tapes

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.