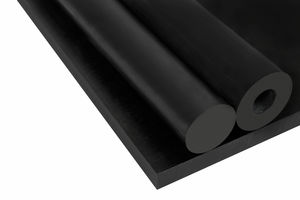

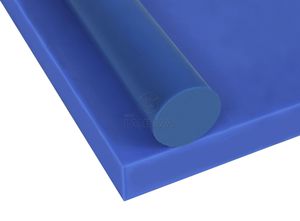

Plate PEEK KETRON® PEEK 1000rodwear-resistantchemical-resistant

Add to favorites

Compare this product

Characteristics

- Shape

- plate, rod

- Protection level

- wear-resistant

- Other characteristics

- chemical-resistant, low-friction

Description

Ketron PEEK 1000® is produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types of Ketron PEEK. Both natural and black Ketron PEEK 1000 ® can be sterilized by all conventional sterilization methods (steam, dry heat, ethylene oxide and gamma irradiation). The composition of the raw materials used for the manufacture of Ketron PEEK 1000 ® is also FDA compliant for plastic materials and parts intended for food contact.

MAIN CHARACTERISTICS

- Very high maximum allowable service temperature in air [250 °C continuously, up to 310 °C for short periods of time]

- High mechanical strength, stiffness and creep resistance, also at elevated temperatures

Excellent chemical and hydrolysis resistance

- Excellent wear and frictional behaviour

- Very good dimensional stability

- Excellent resistance to high energy radiation [gamma- and X-rays]

- Inherent low flammability and very low levels of smoke evolution during combustion

- Good electrical insulating and dielectric properties [except for Ketron HPV PEEK and CA30 PEEK]

APPLICATIONS

- Pump components

- Valve seats

- Bearings

- Rollers

- Gears

- High temperature insulators

- Components exposed to boiling water or steam

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.