- Metrology - Laboratory

- Metrology and Test Equipment

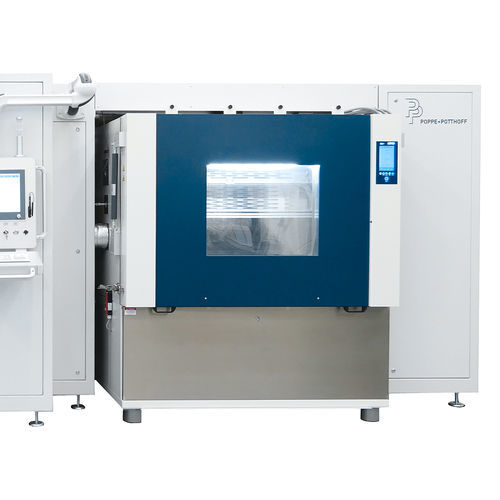

- Burst test bench

- Poppe + Potthoff Maschinenbau GmbH

Pressure impulse test rig burstlife cycledurability

Add to favorites

Compare this product

Characteristics

- Test type

- durability, burst, life cycle, pressure impulse

- Operating mode

- automatic, computer-controlled

- Test material

- for pressurized vessels, for pipes, for plastics, for tubes, for sealing parts

- Sector

- industrial

Description

This cutting-edge test rig is engineered to perform comprehensive burst and pressure pulsation testing on liquid-cooled cold plates utilized in server infrastructures, drawing on methodologies refined within the automotive sector as test standards haven’t been defined yet. Our equipment is crafted to assess and confirm the durability of components and the integrity of seals amidst the dynamic pressures found in cooling circuits. Featuring a hydraulic pressure intensifier, our rigs offer unparalleled precision, achieving reliable and repeatable results across a spectrum of testing scenarios.

With the capability to administer burst pressure tests up to 35 bar (500 psi) and engage in pressure cycle testing at pressures up to 12 bar (175 psi) with the test media PG25, our systems can simulate operational conditions at frequencies reaching 2 Hz. This rigorous testing protocol is indispensable for ascertaining the dependability of cooling solutions integral to the performance of CPUs, GPUs, and related technological apparatus.

By incorporating a hydraulic pressure intensifier, it not only enhances the accuracy of pressure application but also ensures the consistency of test conditions, thereby guaranteeing the reliability of every cold plate tested.

Pressure pulsation with media flow control

Pulsation pressure: 0.2 bar – 12 bar (rel.) at 30 1/min

Burst Pressure: 35 bar

Overpressure test (up to 4 bar for ~1 hour)

Vacuum testing for ~ 30 min

Fluid Temperature Control -20°C to 90°C

Pressure change from negative pressure to positive pressure under medium (without flow control)

PC incl. LabView-Software

Test media: PG 25, water-glycol

VIDEO

Catalogs

No catalogs are available for this product.

See all of Poppe + Potthoff Maschinenbau GmbH‘s catalogsRelated Searches

- POPPE+POTTHOFF test bench

- POPPE+POTTHOFF automatic test bench

- POPPE+POTTHOFF pressure test bench

- POPPE+POTTHOFF industrial test bench

- POPPE+POTTHOFF computer-controlled test bench

- POPPE+POTTHOFF hydraulic test bench

- POPPE+POTTHOFF test bench for the automotive industry

- POPPE+POTTHOFF leak test bench

- POPPE+POTTHOFF valve test bench

- POPPE+POTTHOFF PLC-controlled test bench

- POPPE+POTTHOFF pneumatic test bench

- Universal test stand

- POPPE+POTTHOFF laboratory test bench

- Compact test stand

- Mobile test stand

- Performance test stand

- POPPE+POTTHOFF hose test bench

- POPPE+POTTHOFF test bench for the aeronautical industry

- Flow test stand

- POPPE+POTTHOFF fatigue test bench

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.