- Machine-tools

- Machining Center

- CNC lathe

- PORĘBA Machine Tools

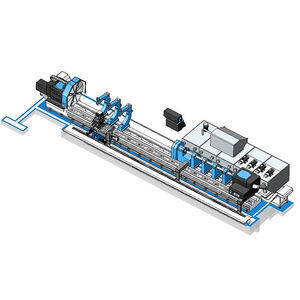

Large workpiece turning center TRP seriesCNC2-axismilling

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 2-axis

- Applications

- for large workpieces

- Associated function

- milling, drilling

- Diameter

650 mm, 740 mm, 930 mm, 1,100 mm

(25.59 in, 29.13 in, 36.61 in, 43.31 in)- Spindle speed

Max.: 2,000 rpm

(12,566.371 rad.min-1)Min.: 2 rpm

(12.566 rad.min-1)- Rapids on Z

4,000 mm/min

(3 in/s)- Nominal power

12 kW, 22 kW, 28 kW, 30 kW

(16.3 hp, 29.9 hp, 38.1 hp, 40.8 hp)- Overall lenght

2,450 mm, 3,270 mm

(96 in, 129 in)- Overall width

2,080 mm, 2,735 mm

(82 in, 108 in)- Overall height

2,000 mm, 2,200 mm

(79 in, 87 in)- Weight

4,000 kg, 4,200 kg, 9,400 kg, 10,700 kg

(8,818 lb, 9,259 lb, 20,723 lb, 23,589 lb)

Description

In their basic version the TRP series (TRP 63 / 72 / 93 / 110) horizontal centre lathes – thanks to the innovative mechanical solutions and the advanced control systems – are the multi-purpose lathes that guarantee productive rough and finish machining.

The TRP series lathes are designed for workpiece machining in the range of turning in accordance with their specifications, especially for machining of large-size shafts. When delivered with special equipment they can operate as horizontal machining centres with turning, drilling and milling capabilities. They can be equipped with an automatic turret, tool attachments, tool and workpiece measuring systems, controlled C axis, workpiece steady rests.

CONTROL SYSTEM

The application of the state-of-the-art CNC system allows for automatic, precise and productive workpiece machining according to a program.

Catalogs

TRP series

6 Pages

Related Searches

- Turning center

- CNC turning center

- 2-axis turning center

- High-precision turning center

- Drilling machine

- 12 tools turning center

- High-rigidity turning center

- High-productivity turning center

- Heavy-duty turning center

- Milling turning center

- Drilling turning center

- Drilling turning machine

- Large part turning center

- Inclined bed turning center

- Boring turning center

- 4 tools turning center

- Horizontal drilling machine

- Deep hole drilling machine

- 4-guideway lathe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.