- Production Machines

- Cutting Machine

- CO2 laser cutting machine

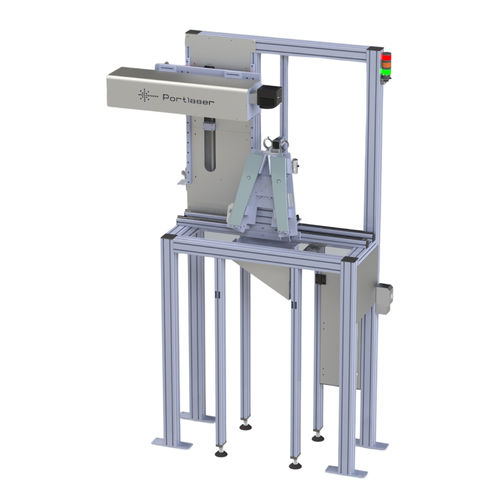

- PORTLASER TECHNOLOGY, LDA

CO2 laser cutting machine for compositesfor plasticsfor injection Sprue

Add to favorites

Compare this product

Characteristics

- Technology

- CO2 laser

- Material

- for plastics, for composites

- Product handled

- for injection Sprue

- Control type

- with control software

- Applications

- for industrial applications, for the automotive industry, for the plastics industry

- Workpiece loading

- manual loading, automated loading/unloading

- Phase

- single-phase

- Configuration

- compact, with fixed table

- Other characteristics

- high-precision, automatic, high-speed, CE, robotic, high-performance, high-efficiency, for mass production, manual, high-power, for large parts, with water cooling, with galvanometric head, economical, custom-made, programmable, with automatic feeder, robotic arm, electric, high-productivity

- Laser power

Min.: 55 W

Max.: 100 W

- Operating pressure

6 bar

(87.02 psi)- Overall length

1,600 mm

(63 in)- Overall width

480 mm

(19 in)- Height

2,390 mm

(94 in)- Power supply

220 V

Description

The Injection Sprues Cutting Station is specifically designed for cutting injection sprues from plastic components, making it ideal for use in production lines. Its unique design allows for seamless integration with robotic systems, where robots (or even a human operator) can efficiently load and unload pieces, maintaining a continuous operation. The machine features a custom-made nest, which securely holds the workpiece in place, ensuring perfect alignment for each cut.

Main features

• CO2 laser with power options of 55 or 100W;

• MTBF over 40,000 hours;

• Seamless integration with robotic systems;

• Equipped with a custom-made nest, facilitating loading by operators or robots;

• Working area from 110x110mm to 175x175 mm;

• Dedicated compartments for efficient collection of cutting waste;

• Automatic Z-axis controlled by software;

• Low maintenance needs;

• Dedicated software compatible with the Windows operating system, supporting the import of PLT, AI, DXF, BMP, PCX, TIFF, JPEG, PNG, DWG, and other file formats;

• Water-cooling system.

Catalogs

No catalogs are available for this product.

See all of PORTLASER TECHNOLOGY, LDA‘s catalogsRelated Searches

- Cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- High-precision cutting system

- High-speed cutting system

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Cutting machine for the automotive industry

- CE cutting system

- High-performance cutting system

- High-efficiency cutting system

- Compact cutting system

- Cutting machine with automatic loader

- CO2 laser cutting system

- Wood cutting system

- High-power cutting machine

- Cutting system with water cooling

- Cutting machine for the electronics industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.