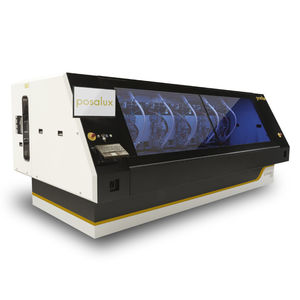

CNC drilling and routing machine Ultraspeed MONO3-axisfor printed circuit boardshigh-speed

Add to favorites

Compare this product

Characteristics

- Type

- CNC

- Number of axes

- 3-axis

- Applications

- for printed circuit boards

- Other characteristics

- high-speed

Description

Innovative and ergonomic design

One, two, three, and six stations available in single, combi, or dual version

X, Y and Z axis with linear motor drives

Workpiece format : 635 x 724 mm (25″ x 28.5″)

XY individual technology available on TRIO model (workpiece format : 610 x 724 mm – 24″ x 28.5″)

Choice from an extensive range of drilling, routing or combination spindles

Spindle speed range from 5’000 to 350’000 rpm

Tool management system with chain, Asian Tool Change (ATC) and cassette

New Posalux CNC 5000 – Powerful digital servo drives for rigid axis control

Advanced concept of Z-axis unit – Increased stiffness, reduced mass

New generation of multi-inserts pressure pad (IPF3) for drilling and routing

Second measuring system for a perfect surface detection in controlled depth routing

Standard and customized clamping systems

CCD camera for registration

Automation – individual loader with up to 22 levels

New concept of Z-axis

Reduced mass

Improved guiding ratio

Higher stiffness

IPF3 – Drilling and routing

Interchangeable Pressure Foot with 3 positions

Configuration with routing brush and large drilling insert

Configuration with small and large drilling insert

Air gap function : air flow through inserts to avoid any scratching of entry foil

Machine versions

Single version : one machining unit per station

Combi version : Two different and alternating machining units per station

Dual version : Two identical machining units per station

Catalogs

Ultraspeed MONO

4 Pages

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- 5-axis CNC machining center

- Rigid CNC machining center

- Drilling CNC machining center

- 4-axis CNC machining center

- Universal CNC machining center

- CNC machining center with linear motor

- Micro-machining machine

- Laser micro-machining machine

- Micro-drilling machine

- CNC micro-drilling machine

- Drilling and routing machine

- EDM micro-drilling machine

- CNC drilling and routing machine

- High-speed micro-drilling machine

- High-speed drilling and routing machine

- Printed circuit board drilling and routing machine

- 3-axis micro-machining machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.