- Electricity - Electronics

- Electronic Component

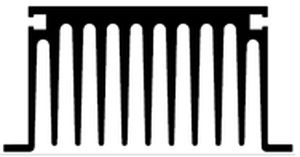

- Aluminum heat sink

- Power Products International

Aluminum heat sink liquid-cooledpower

Add to favorites

Compare this product

Characteristics

- Material

- aluminum

- Options

- liquid-cooled, power

Description

Water cooled or liquid cooled heatsinks are an efficient way to manage complex electronic systems having high concentrated power.

Liquid cooling is fast becoming the preferred solution to dissipate the high power of the latest generation IGBT modules. Power Products International has more than 20 years experience in the development of assembled tube liquid cooled plates. Our partners MeccAl srl are able to provide custom solutions using robust controlled atmosphere brazing processes to optimise localised cooling around heat sources.

CAB Brazing Liquid Cold Plate

• Strong Metal Joint created by Brazing of Metals

• Aluminium Alloy suitable from AL EN AW1xxx,3xxx,6xxx

• Design & Dimensions flexibility to application requirements

• Cooling possible directly under heatsource

• Compact and dense therm. distribution and heat transfer

• Liquid channel design optional with turbulators

• Standard or customized fittings for liquid I/O

• Suitable with electr. non-isolated fluids

• Fitting for almost every application fields

• Designs and solutions developped from our internal R&D

• Short lead time incl. flexible production capacities

Process Sequence

• Components preparation & cleaning

• Addition of Flux and Filler material

• Components Assembly and Clamping

• Drying and Pre-Heating in the Oven

• Brazing in Controlled Atmosphere

• Cooling in the Oven

• Mechanical test and leakage test

• Sandblasting

• CNC Machining & Final QS Control

VIDEO

Catalogs

No catalogs are available for this product.

See all of Power Products International‘s catalogsOther Power Products International products

Thermal management

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.