- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

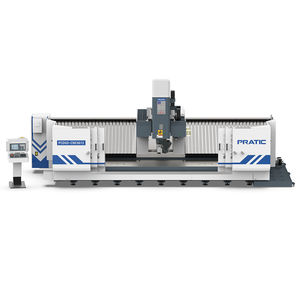

3-axis CNC machining center PYE Seriesverticaltraveling-columnBT 40

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- traveling-column

- Spindle mount

- BT 40, BT 50, CAT40, CAT50, SK40, SK50

- Number of tool stations

- 24 tools, 16 tools

- Associated functions

- milling, tapping, drilling

- Applications

- for large workpieces

- Other characteristics

- high-performance, high-precision, high-rigidity

- X travel

2,500 mm, 4,500 mm, 6,500 mm

(98.43 in, 177.17 in, 255.91 in)- Y travel

650 mm

(25.59 in)- Z travel

700 mm

(27.56 in)- Rotational speed

8,000 rpm, 10,000 rpm

(50,265 rad.min-1, 62,832 rad.min-1)- Power

15 kW, 17 kW

(20.39 hp, 23.11 hp)- Work feed X-axis

15,000 mm/min

(10 in/s)- Work feed Y-axis

15,000 mm/min

(10 in/s)- Tool-changing time

2 s

- Weight

12,000 kg, 16,500 kg, 17,000 kg

(26,455.47 lb, 36,376.27 lb, 37,478.58 lb)- Overall length

6,900 mm, 8,700 mm, 10,900 mm

(271.7 in, 342.5 in, 429.1 in)- Overall width

3,100 mm, 3,200 mm

(122 in, 126 in)- Overall height

3,100 mm

(122 in)

Description

• The machine integrates the function of milling, drilling and tapping

• Matching for processing of various metal parts, such as steel, aluminum, copper etc..

• Widely used in industries of machinery manufacturing, automotive, rail transportation and etc.

- High-performance and robust spindle system meets the most challenging modern processing needs of a wide range of metal materials

- Casting iron bed with strong shock absorption capacity and high physical stability

- Top-class numerical control system with high processing stability

- Intensified moving column structure brings higher rigidity and higher precision

Rapid on X-axis: 60 m/min

Rapid on Y-axis: 28 m/min

Rapid on Z-axis: 28 m/min

X/Y/Z cutting feed rate: 15 m/min

X/Y/X positioning accuracy: 0.05/0.02/0.01 mm

Repeat positioning accuracy: 0.01 mm

Machine height: 3100mm

Machine covered area: 6900-10900*3100mm

Machine weight: 12000-17000 kg

VIDEO

Catalogs

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- High-performance CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- High-productivity CNC machining center

- Column type CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

- Bridge CNC milling machine

- CNC machining center with pallet changer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.