- Products

- PRATIC CNC

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

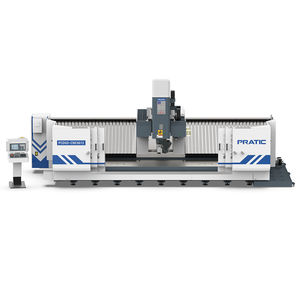

3-axis profile machining center PA Seriesverticalfor aluminumfor steel

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Machined material

- for aluminum, for steel

- Spindle mount

- BT 30, BT 40

- Number of tool stations

- 16 tools, 24 tools

- Associated functions

- milling, tapping, drilling

- Applications

- for the automobile industry, for windows and doors

- Other characteristics

- high-speed, high-performance, high-productivity, high-speed, with pneumatic clamping, high-precision

- X travel

2,500 mm, 4,500 mm

(98.43 in, 177.17 in)- Y travel

400 mm

(15.75 in)- Z travel

450 mm

(17.72 in)- Rotational speed

10,000 rpm, 12,000 rpm

(62,832 rad.min-1, 75,398 rad.min-1)- Power

Min.: 5.5 kW

(7.48 hp)Max.: 11 kW

(14.96 hp)- Work feed X-axis

Min.: 1 mm/min

(0 in/s)Max.: 15,000 mm/min

(10 in/s)- Work feed Y-axis

Min.: 1 mm/min

(0 in/s)Max.: 15,000 mm/min

(10 in/s)- Work feed Z-axis

Min.: 1 mm/min

(0 in/s)Max.: 15,000 mm/min

(10 in/s)- Positioning accuracy

0.015 mm, 0.02 mm, 0.03 mm

(0.00059 in, 0.00079 in, 0.00118 in)- Repeatability

0.01 mm

(0.00039 in)- Weight

6,500 kg, 8,000 kg

(14,330.05 lb, 17,636.98 lb)- Overall length

5,500 mm, 7,700 mm

(216.5 in, 303.1 in)- Overall width

3,200 mm, 3,300 mm

(126 in, 129.9 in)- Overall height

3,300 mm

(129.9 in)

Description

PA series high-speed profiles machining center

• The machine integrates the function of milling, drilling and tapping

• Machining for aluminum frames, copper frames and non-metal materials

• widely used in electronic appliances, customized furniture and other frame processing industries

* The high bed structure effectively prevents water debris from splashing outside the equipment, and at the same time protects important parts

* PA-CNC2500 standard X-axis screw drive and rapid speed up to 48m/min to realize superior dynamic performance and higher acceleration, meets the machining accuracy while improving machining efficiency

* The bottom of the table is designed with a large bevel for chip removal, accelerating the debris falling to the chip receiving tank, which improves the chip removal efficiency and avoids the impact of chip accumulation on machining accuracy.

Parameter

X-axis travel: 2500/4500mm

Y/Z-axis travel: 400/400

Rapid speed: BT30:5.5/7.5kW; BT40:7.5/11kW

Max. speed: 10000/12000rpm

VIDEO

Catalogs

No catalogs are available for this product.

See all of PRATIC CNC‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.