Bench-top micrometer 50 seriesoutsideinsidedigital

Add to favorites

Compare this product

Characteristics

- Type

- bench-top

- Measurement

- outside, inside

- Display

- digital

- Other characterisitcs

- high-precision

- Measuring range

Max.: 292 mm

(11.496 in)Min.: 0 mm

(0 in)- Resolution

0.025 µm

Description

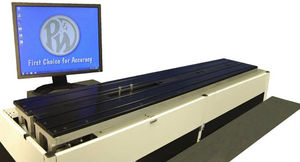

The Standard of Accuracy

The definitive bench micrometer, the Universal Supermicrometer (USM), offers the advantage of being two instruments in one, by providing the ability to measure both internal and external parts, gages or standards. Additionally, as a high precision, direct-reading metrology instrument, it is equally capable of checking critical components such as shafts, bores, O-rings, or just about any ID/OD part. The USM digital bench micrometer can serve as both the heart of your in-house gage calibration needs and a high accuracy part inspection system.

The Universal Supermicrometer® measures:

•Length standards

•External threads

•Ball bearings

•Plugs & pins

•Plain ring gages

•Setting Standards (Frames, Rods)

•Dial, digital and test indicators

•Gears / Splines

•Tapered pipe threads / API

•Your Precision Part

Features & Benefits of the Universal Supermicrometer®:

•Two models to choose from -

•Multi-axis (Model 504: part # U307000) - Measurement table includes swivel, center, tilt and elevation adjustments. The Model 504 is a direct replacement to the obsolete Internal Supermicrometer Model TG2100 and G2100.

•Single-axis (Model 501: part # U307042) - Measurement table includes elevation adjustment.

•Mechanical and Thermal Stability - A rugged cast iron base and thermally stable composite materials insure repeatable and reproducible results

•Linear Encoder with Zero Abbe Offset - A high precision glass scale located along the measurement axis eliminates Abbe offset errors that reduce overall measurement uncertainty

Catalogs

UNIVERSAL SUPERMICROMETER

4 Pages

Other Pratt & Whitney products

Universal (ID/OD) Measuring Instruments

Related Searches

- Measuring machine

- Micrometer

- Automatic measuring system

- High-precision measuring machine

- Measuring system for industrial applications

- Parts measuring machine

- Distance measuring machine

- Diameter measuring machine

- Digital micrometer

- Laser measurement system

- Outside micrometer

- Laboratory measuring machine

- Length measuring machine

- Measuring system for the automotive industry

- Thickness measurement system

- Inside micrometer

- Analog micrometer

- Calibration measuring machine

- High-speed measuring machine

- Roundness measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.