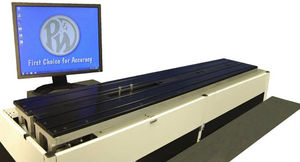

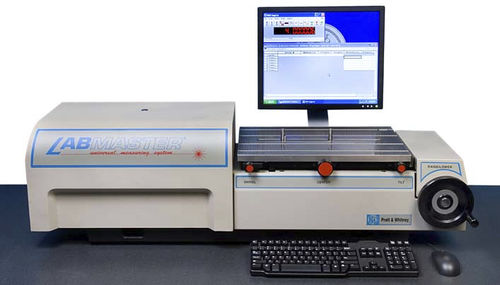

Diameter measuring machine LMU-175lengththicknesslaser

Add to favorites

Compare this product

Characteristics

- Measured physical value

- diameter, length, thickness

- Technology

- laser, interferometric

- Measured material

- bearing

- Applications

- laboratory, calibration

- Other characteristics

- high-precision

Description

The Standard of Accuracy ...and the most popular instrument in industry for over 31 years!

With instrument uncertainty to 2 millionths of an inch (50 nanometers), the Labmaster Universal - Model 175 is suitable for virtually all Internal (ID), external (OD), and same side dimension (SD*) measuring applications. This laser-based universal length measuring machine (ULM) has been developed by Pratt & Whitney for gage calibration laboratories that need to precisely measure length, outside diameter, inside diameter, pitch diameter, lead, major/minor diameter, taper, linear displacement, and thickness.

High accuracy is maintained by its laser interferometer, zero Abbe offset design, and large measuring table (100 lb [45 kg] capacity) with center position, height, pitch, and yaw controls. The computer-controlled precision air bearing slide and gaging probes remove operator-influenced errors commonly observed with traditional gaging methods by maintaining constant force. It also greatly minimizes wear and tear to both the measuring standards and the instrument. Air bearings are also highly resistant to contamination and have inherent vibration-damping properties that increase stability and accuracy. The large measuring table also acts as a soak plate. By design, the weight of the part will not affect the measurement because the table support is independent of the air bearing slide. This is not the case with traditional methods.

Catalogs

No catalogs are available for this product.

See all of Pratt & Whitney‘s catalogsOther Pratt & Whitney products

Universal (ID/OD) Measuring Instruments

Related Searches

- Measuring machine

- Micrometer

- Automatic measuring machine

- High-precision measuring machine

- Measuring system for industrial applications

- Parts measuring machine

- Distance measuring machine

- Digital micrometer

- Laser measurement system

- Diameter measuring machine

- Outside micrometer

- Laboratory measuring machine

- Length measuring machine

- Measuring system for the automotive industry

- Thickness measurement system

- Inside micrometer

- Calibration measuring machine

- Analog micrometer

- High-speed measuring machine

- Roundness measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.