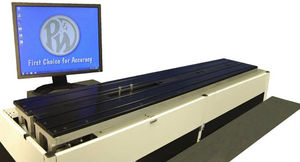

Diameter measuring machine LMU-1000M laserinterferometricbearing

Add to favorites

Compare this product

Characteristics

- Measured physical value

- diameter

- Technology

- laser, interferometric

- Measured material

- bearing

- Applications

- for industrial applications, calibration

- Other characteristics

- high-precision

Description

The Standard of Accuracy ...and the most popular instrument in industry!

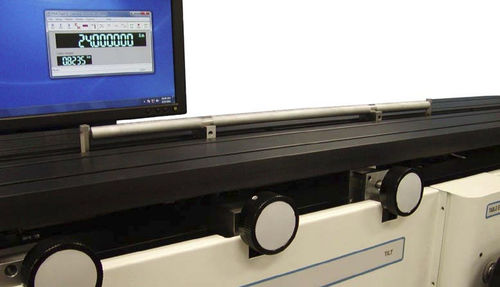

With a 40 inch (1016mm) direct reading range and an 80 inch (2032mm) capacity with optional probes, this laser-based Universal Measuring System is designed for high accuracy, ID/OD/SD* gage calibration and part measuring. Swivel, centering, tilt, and elevation knobs are all standard and easy to use. Features include laser interferometer, computer control, air bearings, bi-directional probes, constant measuring force, and flexible fixturing. These features offer guaranteed repeatability and operator independent reproducibility with unmatched speed.

With appropriate accessories, the LABMASTER Universal 1000M is capable of measuring rings (threaded & non-threaded), gage blocks, plugs (threaded & non-threaded), dial/test indicators, gage wires, micrometer heads, pin gages, tapered plugs (threaded & non-threaded), end standards, micrometers, and snap gages, all with NIST traceability. Only a handful of traceable masters, such as blocks, rings, etc. are needed (not included). The LABMASTER Universal 1000M can also measure a wide range of specialty applications such as ID/OD bearings (radial/axial clearance), balls, shafts, optics, as well as your precision parts. The LABMASTER Universal 1000M includes a current model computer loaded with GageCal, Pratt & Whitney’s Windows based measurement and control software. GageCal has predefined application screens and automatically enters tolerances for various types of measurements such as blocks, rings, plugs, and threads. P&W is accredited in accordance with the recognized International Standard ISO/IEC 17025:2005 by A2LA.

Catalogs

No catalogs are available for this product.

See all of Pratt & Whitney‘s catalogsOther Pratt & Whitney products

Universal (ID/OD) Measuring Instruments

Related Searches

- Measuring machine

- Micrometer

- Automatic measuring machine

- High-precision measuring machine

- Measuring system for industrial applications

- Parts measuring machine

- Distance measuring machine

- Diameter measuring machine

- Digital micrometer

- Outside micrometer

- Laser measurement system

- Laboratory measuring machine

- Length measuring machine

- Measuring system for the automotive industry

- Thickness measurement system

- Inside micrometer

- Analog micrometer

- Calibration measuring machine

- High-speed measuring machine

- Roundness measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.