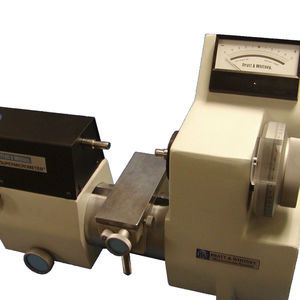

Calibration interferometer VLM200for thickness measurementdigitallaser

Add to favorites

Compare this product

Characteristics

- Applications

- calibration, for thickness measurement

- Options

- laser, high-accuracy, digital

Description

The Standard of Accuracy

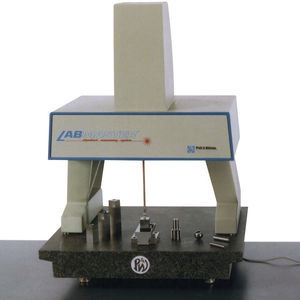

Your solution for vertical measuring is the Laseruler which is laser-interferometer-based for very high accuracy. Measure height and thickness of precision film, parts, and gages with complete confidence.

Our exclusive digital interferometer measures the dimension of the specimen by comparing the measurement probe position to the wavelength of a Helium Neon (He-Ne) laser light source, effectively coupling the wavelength of light to the part being measured. Our patented laser path is in-line with the measurement axis to eliminate Abbe offset error.

The operator simply presses a button or footswitch and the instrument does the rest.

The Laseruler® measures:

•Film Thickness

•Optical Components

•Gage Blocks

•Balls / Spheres

•Ball Bearings

•Coating Thickness

•Coating Thickness Standards

•Plug & Pin Gages

•Thread Wires

•Aerospace Parts

•Automotive Parts

•Medical Instruments

Features & Benefits of the Laseruler®:

•Rigid design - For maximum repeatability and reproducibility

•Motorized probe - Improves system stability and eliminates operator influence

•Digital laser interferometer - Guarantees maximum resolution, traceability, and performance

•Two-step calibration - Advanced time saving feature allows for calibration in only 30 seconds.Mastering with two, NIST traceable blocks, allows continuous, accurate measurement over the full direct reading range. This provides significantly higher levels of productivity when compared to single point comparators. Only a handful of traceable masters, such as blocks, balls, etc. are needed (not included).

•Automatic cycling - Increases measurement throughput rate when measuring standard gage sets

Catalogs

Other Pratt & Whitney products

Outside Dimension (OD) Measuring Instruments

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.