- Production Machines

- Cutting Machine

- Diamond wire cutting machine

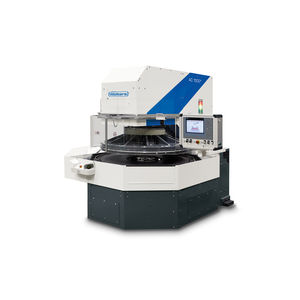

- Precision Surfacing Solutions GmbH & Co. KG

Diamond wire cutting machine DW 292-300multi-wirefor monocrystalline siliconblocks

Add to favorites

Compare this product

Characteristics

- Technology

- diamond wire, multi-wire

- Material

- for monocrystalline silicon

- Product handled

- blocks, wafer

- Control type

- NC

- Applications

- for the semiconductor industry

- Configuration

- compact

- Other characteristics

- high-speed

- Maximum cutting height

305 mm

(12 in)- Tube diameter

305 mm

(12 in)- Cutting speed

20 m/s, 35 m/s

(65.617 ft/s, 114.829 ft/s)- Acceleration

8 m/s², 12 m/s²

(26 ft/s², 39 ft/s²)- Overall length

3,610 mm

(142 in)- Overall width

1,380 mm

(54 in)- Height

2,860 mm

(113 in)- Weight

9,300 kg

(20,502.99 lb)

Description

The DW292-300 is specifically designed for slicing monocrystalline silicon blocks with up to 300mm diameter into high quality wafers for the semiconductor industry.

The new developed DW292-300 is capable to be run with slurry as well as diamond wire and includes sophisticated features to improve wafer quality such as warp and waviness

Longer wire web length as well as higher wire speed and wire acceleration enable an increased throughput per machine and year. Usage of very thin diamond wire is possible as a result of optimized inertia of moving parts, less deflection rollers and shorter wire path.

The DW292-300 is highly insensitive to temperature fluctuation and vibrations due to its compact and robust mineral cast frame and rigid design.

Operation is safer, easier and faster thanks to higher process automation and new intuitive HMI with dialog-based production assistant.

Your benefits:

High quality wafer

Increased throughput

Robustness and durability

Higher process automation

Easy and safe operation

Catalogs

No catalogs are available for this product.

See all of Precision Surfacing Solutions GmbH & Co. KG‘s catalogsOther Precision Surfacing Solutions GmbH & Co. KG products

Flat Finishing

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.