Precision Die Systems is dedicated to pushing the boundaries of manufacturing technology to deliver innovative solutions for our clients. Our team of experts is committed to optimizing production processes, offering customized die design, and enhancing coating performance to meet the evolving demands of the industry.

General Specifications

Standard Die Body Flatness/Straightness Tolerance: 0.0001 inch (2.54 microns) maximum deviation over the entire length of each die half

Slot Die Positioner: repeatability and accuracy within 0.0001 inch (2.54 microns)

Coat width: up to 120.00 inches (3048 mm)

Lip Opening: determined via body shims or adjustable lip opening (0-20 mil/ 0-508 micron)

Fluid Viscosity Range: 1 – 500,000cP

Number of Layers Coated by Types of Dies:

Slot Dies: 1-3 layers

Slot Curtain Dies: 1-3 layers

Slide Dies: Unlimited number of layers

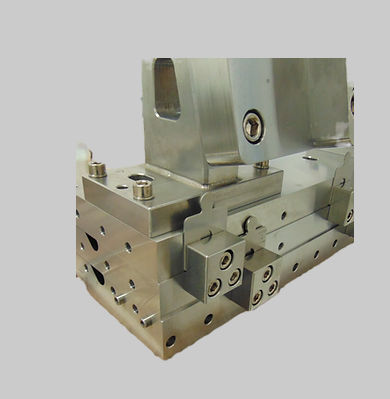

Die Body Construction:

Standard: Constructed of 15-5 ph stainless steel @ condition H1025.

Optional: Constructed of 316L SS, Hastelloy or Titanium

All Slot Dies Include:

(4) 302-304 stainless steel or (8) poly shims

18-8 Fasteners

Nickel/Teflon Coating

(1) Feed Adapter

Body offset feature

Body bolt torque sequence and torque valves engraved in die body

Tool kit with torque wrench included

Instructions and manual

Custom shipping container(s) such as custom built powder coated steel or aluminum

Available Options:

Multi-layer coating is accomplished via multiple manifolds

Replaceable lip inserts

Manifold Plugs

Die hinge option to open the upper half in place to 135 degrees for easy access