- Detection - Measurement

- Electrical Measurements

- Magnetic sensor

- PRECITEC OPTRONIK

- Products

- Catalogs

- News & Trends

- Exhibitions

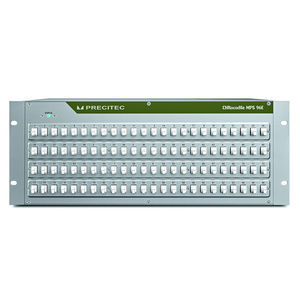

Magnetic field sensor HR

Add to favorites

Compare this product

Description

The Field Sensor HR is a unique way of analyzing what's under the surface of an opaque object – and doing it cost-effectively through an ultra-compact probe. This sensor's laser thermography visualization technology enables you to spot any cracks, defects, delaminations, pores, bad adhesion, lack of fusion or any other abnormalities under the surface of any material.

Paints, laquers, varnishes, metallic, ceramic or organic layers, inks, enamels, resins, adhesives: whatever the coating or substrate, this sensor will measure the entire surface by capturing over 110,000 points in 1 second – and analyze what's underneath it too.

Suitable applications

The extremely high resolution of the Field Sensor HR allows precise analysis of parts that are ultra-small or display very complex, miniaturized patterns. This is particularly beneficial in the field of consumer electronics or semiconductors. As the cutting-edge subsystems of this ultra-compact sensor are concentrated in the smallest possible space, the Field Sensor HR can be integrated into a wide variety of industrial applications, embedded in all types of automation solutions, or duplicated to simultaneously analyze several neighboring surfaces of interest.

Advantages

• Cost-efficient area analysis: Measures an entire surface in a single shot and detects abnormalities under the surface of any opaque material through non-contact, non-destructive photothermal technology

• High-speed measurements: Captures over 110,000 measurement points in just 1 second

• Convenient versatility: Precise measurements on a wide range of part shapes, curvatures and surface structures with a high temperature tolerance (hot or cold)

Catalogs

CHRomatic Sensors

2 Pages

Measuring Sensors

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.