- Metrology - Laboratory

- Metrology and Test Equipment

- 2D scanner

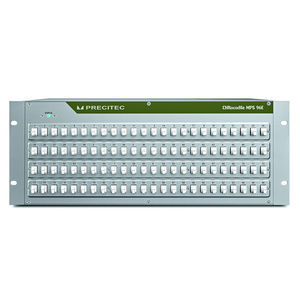

- PRECITEC OPTRONIK

- Products

- Catalogs

- News & Trends

- Exhibitions

XY scanner measurementinspectionoptical

Add to favorites

Compare this product

Characteristics

- Number of axes

- XY

- Applications

- measurement, inspection

- Technology

- optical

- Other characteristics

- high-speed, non-contact

- Measuring distance

125 mm, 200 mm

(4.9 in, 7.9 in)

Description

Precitec's Flying Spot Scanner (FSS) enables high-speed OCT imaging for thickness and topography, and is combinable with various CHRocodile 2 IT sensors to create a smart inspection system. The FSS features pioneering one-of-its-kind technology enabling high-speed non-contact area inspection for inline and offline quality assurance and 3D measurement on a wide range of materials and surfaces.

Advantages

• Replaces X-Y motion system

For high-speed area inspections in offline and inline quality control processes the Precitec Flying Spot Scanner replaces an entire measuring system – there are no additional linear X-Y axes required. The mechanical linear movement of the X-Y axes is replaced by an optical measurement guided via a sophisticated optical system.

• Set up your own scanning path for any kind of material

Only the relevant areas are scanned, and the scan shapes and filters are freely definable. The non-contact 3D imaging system enables measurements on reflecting surfaces – even through protective foil. The telecentric imaging minimizes measurement errors due to angles, because light angle stays constant within the scan area. This also reduces shadowing.

• Saves time and money

The Precitec Flying Spot Scanner's outstanding scanning speed, in combination with the CHRocodile 2 IT's fast measuring rate of 70 kHz, enable in-line use with short inspection cycles and cuts the cost of offline and inline quality controls.

Technical data

• Measurements/second: up to 70 kHz

• Measuring range: depends on selected CHRocodile 2 IT sensor

VIDEO

Catalogs

No catalogs are available for this product.

See all of PRECITEC OPTRONIK‘s catalogsRelated Searches

- Thickness measuring machine

- Measurement scanning system

- Coating thickness gauge

- Inspection scanning system

- 2D scanning system

- High-speed scanning system

- Stationary thickness measuring machine

- Optical scanning system

- Precision thickness measuring machine

- Wall thickness measuring machine

- Material thickness gauge

- Film thickness measuring machine

- Non-contact scanner

- Plastic thickness gauge

- Non-contact thickness measuring machine

- Compact thickness gauge

- Benchtop thickness gauge

- Optical thickness gauge

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.